Fuel will be powering vehicular technology because of its high efficiency and insignificant emissions, which means less pollution. This is good news especially when our climatic conditions are at stake. Battery-powered cars are now commonly plying the roads but FCs use hydrogen to produce electricity in order to power the electric motor. While a lot of researchers around the world have been at it, a research team lead by Dr. Naseem Iqbal from United States- Pakistan Center for Advanced Studies in Energy (USPCAS-E), Associate professor for Energy Systems Engineering, his Ph.D. student Saadia Hanif, at USPCAS-E, NUST, and Professor Dr. Kannan Arizona State University, claim to now have found the low loading of platinum on catalyst which can now perform at best in fuel cell.

Fuel will be powering vehicular technology because of its high efficiency and insignificant emissions, which means less pollution. This is good news especially when our climatic conditions are at stake. Battery-powered cars are now commonly plying the roads but FCs use hydrogen to produce electricity in order to power the electric motor. While a lot of researchers around the world have been at it, a research team lead by Dr. Naseem Iqbal from United States- Pakistan Center for Advanced Studies in Energy (USPCAS-E), Associate professor for Energy Systems Engineering, his Ph.D. student Saadia Hanif, at USPCAS-E, NUST, and Professor Dr. Kannan Arizona State University, claim to now have found the low loading of platinum on catalyst which can now perform at best in fuel cell.

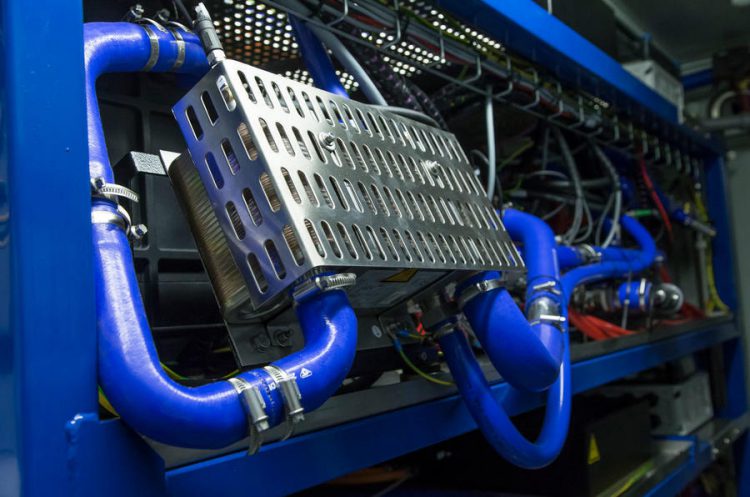

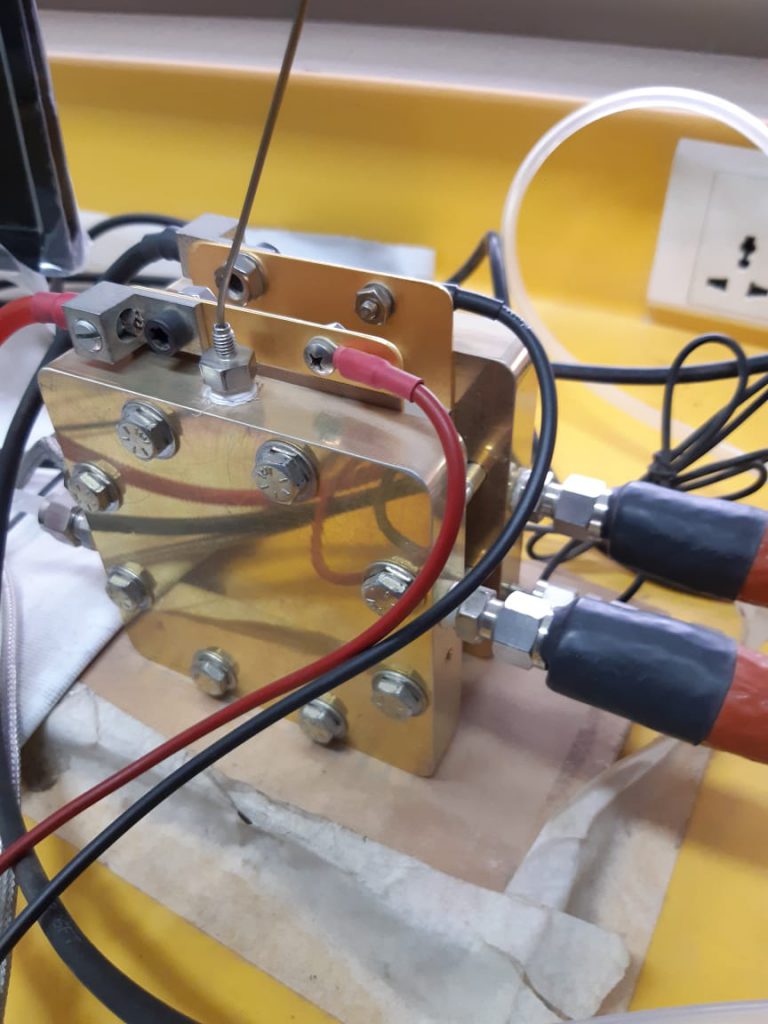

The team developed a highly active and durable catalytic system for PEM fuel cell by minimizing the platinum loading. The performance of non–precious metal-based catalyst is comparable to commercial Pt/C catalyst. They focused on reducing the platinum in fuel cell catalysts while addressing catalyst activity and stability in a cost-effective way. One of the reasons why platinum had to be reduced, firstly because it cannot be synthesized, secondly the high cost and thirdly being a threat to the environment causing global warming.

The cost has long been the biggest obstacle in the commercialization of fuel cell technology worldwide. The dominant factor is the use of expensive material as Platinum, as an active metal catalyst to be used in fuel cells. High-performance cathode catalysts with a minimum platinum amount for the electro-catalyzed oxygen reduction reaction (ORR) in PEM Fuel Cells remain as a significant challenge for commercial application.

“The enhanced activity and durability of catalyst are credited to the synergistic impact of N-doped nano-porous carbon originated from NiCo-ZIF and the defect rich carbon support to anchor Pt/Pt alloy nanoparticles. Our PtNiCo/NC electrocatalyst in single-cell activity showed a peak power density of 1070 mW. cm−2 which is ˜15% increase from commercial Pt/C with same Pt loading at identical testing conditions” explained Saadia.

An international collaboration of USPCASE NUST with Arizona State University was an important factor in the research team’s results. Combining technical capabilities in fuel cell research, joint discussions and physical and chemical knowledge gained from experiments resulted in a model showing how catalysts can be designed with the best performance.

However, the team admits there is a way to go in seeking even greater efficiency. “Our catalyst is performing better than commercial Pt/C and achieving DOE 2020 targets (minimum Pt loading of 0.125 mg/cm2) in the hydrogen fuel cell,” says Dr. Naseem Iqbal, adding that the Pt loading would have to decrease further to see widespread adoption of the fuel cell technology.

(More information: Saadia Hanif, Xuan Shi, Naseem Iqbal, Tayyaba Noor, Rehan Anwar, A.M. Kannan, ZIF derived PtNiCo/NC cathode catalyst for proton exchange membrane fuel cell, Applied Catalysis B: Environmental, Volume 258, 2019, 117947, https://doi.org/10.1016/j.apcatb.2019.117947)

The author is an Associate Professor at USPCAS-E NUST, and can be reached at naseem@casen.nust.edu.pk

The author is an Associate Professor at USPCAS-E NUST, and can be reached at naseem@casen.nust.edu.pk