Dr. Riaz Ahmad Mufti and his team from SMME NUST have designed and developed a Piston Profile Inspection System for a Local OEM. The aim of this project was the localization of development of a high precision inspection system for local automotive industries, import substitution and to save foreign exchange.

Pakistan’s Automotive Industry and its associated local equipment and accessories manufacturers are major contributors to the local economy. The country has exported tractors worth US $ 47 million in FY2021. During July-March FY2022, Pakistan’s exports of tractors have been US $ 29.9 million. With exception of a few intricate parts over 90% of tractor parts are made in Pakistan. With Pakistan targeting to export more and more tractor each year, it must strictly comply with international standards.

Piston is an extremely important component of an International Combustion Engine, and its dimensional accuracy and geometrical profile must conform to strict tolerance standards. Off-the-shelf Piston Profile Inspection and Measurement Systems are available in the international market. These measurement systems are extremely expensive, and the Inspection Equipment Manufacturers normally do not customize the software as per the requirements of the local operator.

Small vendors of the industry are reluctant to adopt the high-tech solution and machinery as it is very expensive, and it doesn’t seem viable to them due to their small business size. There are numerous semi-automatic machines that can be made locally in Pakistan with little R&D effort such as vacuum forming machine, wheel balancing machine, wheel alignment machine, automatic hose crimping machine etc. Quality inspection machines are still largely imported by Pakistan. The development of these specialized machines mainly requires system integration which requires the knowledge of sensors, actuators, software, and data acquisition.

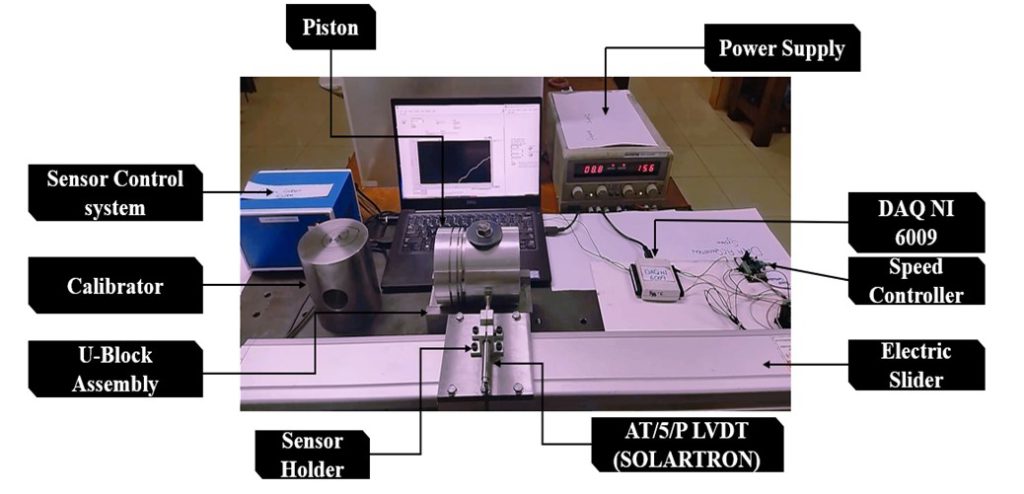

This industrial project was undertaken for a local Tractor Manufacturing Company, Millat Tractors Limited. The company desired a cost-effective and easy to use Piston Profile Inspection System. A customized Piston Profile Test Rig was designed, fabricated, and instrumented. The profile is measured by holding the piston using a U-block mechanism and taking readings over defined intervals. A Linear Variable Differential Transformer (LVDT) sensor is utilized to take the readings with an accuracy at submicrons level. The accuracy and precision requirements are specified by the manufacturing drawings provided by the OEM. The design of machine components is dictated by the dimensional constraints rather than stress and loading conditions since most components are stationary and are light in weight. The design is optimized to take readings along the length of the skirt to measure its profile. Off-the-shelf solutions are available in the international market which costs about 6 to 8 times more than our developed solution. The accuracy and repeatability were within ±2 microns. A bespoke software in LabVIEW was designed for monitoring the Piston Profile and for recording the data. National Instruments Data Acquisition Card with a sampling rate of 48 kS/ having an analogue input resolution of 14 bits was used in the development of this inspection system. The developed system has been presented in the following figure.

The Need for Piston Inspection Machine in Pakistan

With import restrictions and new export avenues for Pakistan’s Tractor OEMs, it is the need of the hour to locally design and develop such inspection machines which can not only inspect locally manufactured high precision parts as per internal standards but can also offer a customized software for the local technical operator for ease of use.

Licensing of this Machine to the Industry

We are offering the licensing of this technology to any industrial partner based on the NUST Technology Transfer policy.

The author is an Assistant Professor at the School of Mechanical & Manufacturing Engineering, National University of Sciences and Technology (NUST). He can be reached at usmanbhutta@smme.nust.edu.pk.

Researcher’s Profile: https://shorturl.at/ajxAB

![]()