Growing worldwide demand for energy met by burning fossil fuels has severe environmental effects and wider socio-economic repercussions. Developing countries like Pakistan are struggling to realize and plan the energy-environment-economic nexus. Pakistan’s heavy reliance on fossil fuels results in hefty import bills and a significant financial burden at the local, regional, and national levels. In comparison, the production and use of renewable energy is a reliable way of import substitution, self-sufficiency, and a sustainable energy system. Further, renewable energy promises socio-economic prosperity, human well-being, and environmental safety.

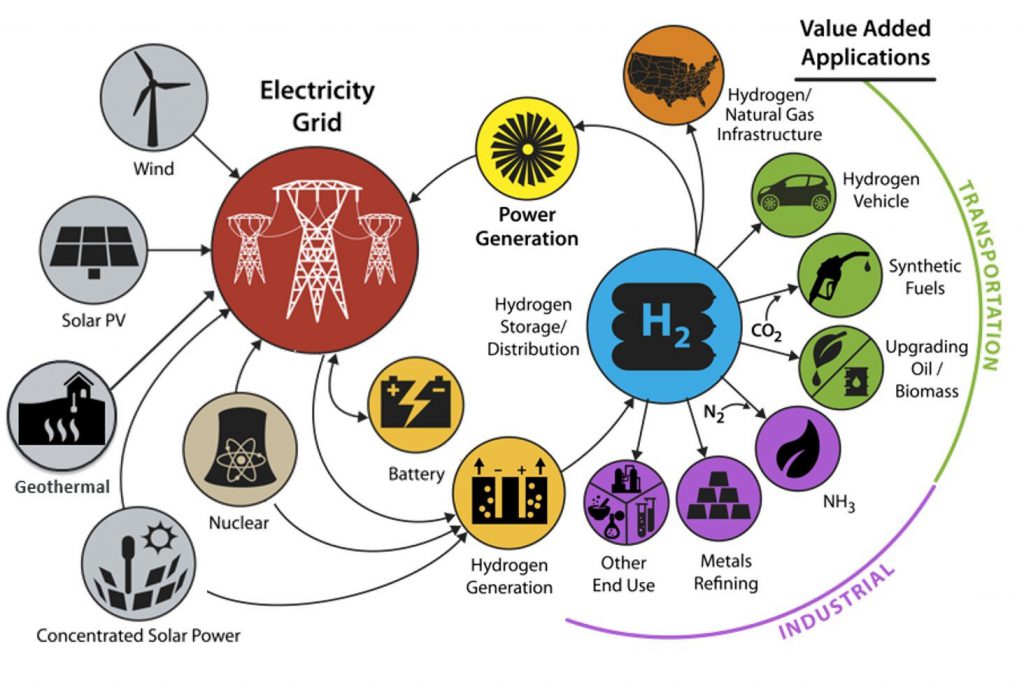

So, the need of the hour is to produce an alternative energy source that should be renewable and cheap. Hydrogen is the best alternative as it can be produced from several sources such as water and biomass. Hydrogen has high energy content, so it is a frequent component in rocket fuel, but numerous technical challenges prevent creating a large-scale hydrogen economy. These include the difficulty of developing long-term storage, pipelines, and engine equipment; a relative lack of off-the-shelf engine technology that can currently run safely on hydrogen; safety concerns due to the high reactivity of hydrogen fuel with environmental oxygen in the air; the expense of producing it by electrolysis; and a lack of efficient photochemical water-splitting technology. The hydrogen economy is nevertheless slowly developing as a small part of the low-carbon economy.

A research team at NUST School of Natural Sciences (SNS), led by Dr. Manzar Sohail and in collaboration with researchers at GCU and LUMS Lahore, have designed this project for the production of electrocatalysts, photocatalysts, and hybrid porous materials for hydrogen production and storage. Green hydrogen production will be used in fertilizer manufacturing and hydrogen fuel-based vehicles. The project will rationalize the adoption of innovative renewable technologies in Pakistan to meet its sustainable development goals.

Hydrogen production is a large and growing industry: with as of 2019, about 70 million tons of dedicated production per year. As of 2019, fertilizer production and oil refining are the main uses. About half is used in the Haber process to produce ammonia (NH3), which is used directly or indirectly as fertilizer. The other half of current hydrogen production is used to convert heavy petroleum sources into lighter fractions suitable for fuels. As of 2019, almost all hydrogen production is from fossil fuels and emits 830 million tons of carbon dioxide per year. Consequently, there is a need to develop cleaner and cheaper hydrogen production and storage pathways to benefit from the hydrogen economy concept truly. Figure 1 summarizes different pathways for the production of hydrogen and its uses.

In the proposed project, hydrogen will be produced via water-splitting, and then this hydrogen can be stored via Adsorption/Absorption. Following are some of the aims of the project:

- Developing new materials and systems for hydrogen production reduces electricity costs and improved efficiency

- Developing new designs of electrolysis systems with lower-cost materials and advanced manufacturing methods to reduce capital costs

- Develop low-cost hydrogen production from electrolysis using solar materials as electricity sources

The proposed project brings together great minds from national and international institutions with diverse expertise and vast experience in materials design, nanotechnology, electrochemistry, reaction kinetics, and organic electronics. All members of the proposed team have held faculty positions in well-reputed universities/institutions and individually managed many research projects in the past, which speaks to their commitment and excellent managerial skills. PI and Co-PIs have a proven record of successful scientific research career in foreign and national universities/institutions demonstrated by many high impact factor publications in some of the top peer-reviewed and highly cited journals, such as Nature Materials, Advanced Materials, Nature Communications, Journal of the American Chemical Society, Angewandte Chemie, Inorganic Chemistry, Organometallic, Macromolecules, and Polymer Chemistry. In addition, the proposed team members have several awards and patents to their name. Current working positions of proposed team members allow them to access advanced laboratory and experimental facilities, thus multiplying the impact of their collaboration and paving the way to an excellent cross-institutional collocation.

The author is a Professor in the Department of Chemistry at School of Natural Sciences, National University of Sciences and Technology (NUST) and can be reached at manzar.sohail@sns.nust.edu.pk.