Biodegradable packaging is an important topic that has been gaining more attention in recent years. With the increasing awareness of the impact of plastic waste on the environment, more and more people are looking for sustainable alternatives to traditional packaging materials. One of the most promising options is biodegradable packaging, which is made from natural materials that can break down easily in the environment.

Unlike traditional packaging materials such as plastic and Styrofoam, biodegradable packaging is made from natural materials that can be broken down by microorganisms in the environment. This includes materials such as paper, cardboard, and plant-based plastics. These materials are not only more environmentally friendly but also less harmful to animals and wildlife. Ref. [1]

Styrofoam is a petroleum-based product widely used as packing material. It is lightweight cellular plastic material consisting of small hollow spherical balls that are expanded through a molding process in different sizes and shapes. Its durable material used in numerous applications such as packing fragile items to insulate buildings. On the other hand, it has drawbacks as it eventually becomes solid waste, and does not degrade for several years causing serious damage to the environment and living organisms. Styrofoam releases hazardous pollutants which can severely impair lung function and lead to respiratory illness. Ref. [2]

In our lab at School of chemical and materials engineering (SCME), an environment friendly alternative has been designed which is based on biowaste and naturally sourced binding material. The material fabricated has comparable properties with expanded polystyrene and cheaper option as well. Biodegradable material obtained from different waste like plants and animals is used. Binding material, preferably plant derived material is used for binding biodegradable material.

One of the biggest benefits of biodegradable packaging is its contribution to reduce waste. Traditional packaging materials can take hundreds of years to decompose, which can linger in the environment for a long time. However, biodegradable packaging can break down much faster, reducing the amount of waste that ends up in landfills and the ocean. This can help to mitigate the negative impact of plastic waste on the environment and the creatures that live there.

Biodegradable packaging developed is made from renewable resources. This means that it can be produced in a more sustainable way and does not contribute to the depletion of finite resources such as fossil fuels. This will reduce the environmental impact of packaging production and make it more sustainable.

Biodegradable packaging also has the potential to reduce the amount of greenhouse gases emitted during the production process. For example, plant-based plastics made from corn starch can be produced with less energy and release less carbon dioxide compared to traditional petroleum-based plastics. This can help to mitigate the negative impact of packaging production on climate change. Ref. [3]

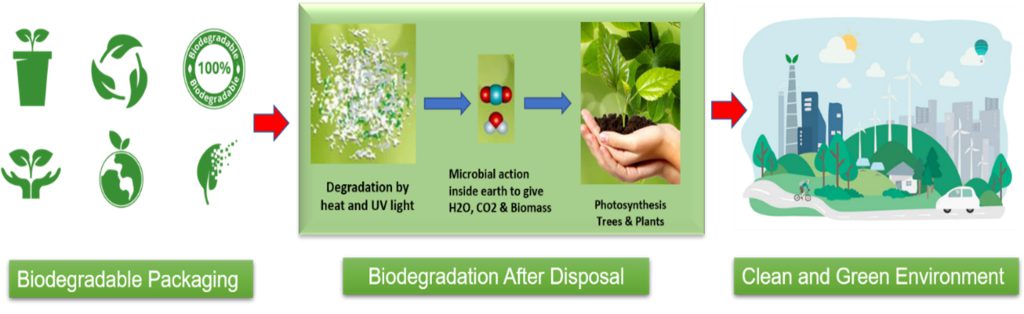

The process of biodegradation starts by exposure to sunlight, air, and moisture, which encourage the growth of microorganisms that feed on the organic matter in the packaging. The result is the breakdown of the packaging into smaller organic compounds, such as carbon dioxide and water, which are then absorbed by the environment. The process typically takes several months to a few years, depending on the specific material and environmental conditions. Ref. [4]

It is beneficial for a country because it helps to reuse waste material in a useful way. Biodegradable packaging can lead to cost savings for businesses and consumers. It eliminates the need for costly disposal and clean-up of non-biodegradable packaging materials. Biodegradable packaging will promote sustainable development by reducing the dependence on non-renewable resources and promoting a circular economy, where waste is minimized, and resources are reused and recycled. It will also improve the health and well-being of citizens by reducing the exposure to harmful chemicals and pollutants associated with traditional packaging materials. Many industries that manufacture electronic items use such types of packaging to protect their items from breakage. Hence, these packaging are cost effective and environment friendly and beneficial for the country.

In conclusion, biodegradable packaging is a promising solution for reducing waste and protecting the environment. With the increasing awareness of the impact of plastic waste on the planet, more and more researchers are looking for sustainable alternatives to traditional packaging materials. As the demand for sustainable packaging options increases, the price of biodegradable materials is likely to decrease, making it more affordable for companies to switch to eco-friendly packaging options. It’s a win-win situation for both the environment and the businesses.

References

- JBM Packaging. (2021, August 26). Biodegradable, Compostable, Sustainable Packaging Options. https://www.jbmpackaging.com/sustainable-packaging/biodegradable-packaging/

- County, C. (n.d.). The Facts on Styrofoam: Reduce and Reuse.

- D.S.Achilias, C. P. (2007). Chemical recycling of plastic wastes made from polyethylene (LDPE and HDPE) and polypropylene (PP). Elsevier Journal of Hazardous Material.

- Gibbens, S. (What you need to know about plant-based plastics). What you need to know about plant-based plastics.

The author is HoD Research at School of chemical and materials engineering (SCME), Department of Chemical Engineering, National University of Sciences and Technology (NUST). He can be reached at m.b.k.niazi@scme.nust.edu.pk.

Research Profile: https://bit.ly/3YpYnxn

![]()