Introduction

Regular cleaning and inspection of conduits and pipes is essential for maintaining their strength and safety and extending their life. Nevertheless, pipeline cleaning by hand is an inefficient use of resources in terms of time and money, necessitating a large staff and endangering worker safety. Therefore, to get beyond the drawbacks of conventional methods, automated cleaning is preferred. For the long-distance transfer of raw commodities such as water, oil, petroleum, gases, and industrial waste, pipelines are a vital means of transportation in many sectors. Pipe damage may have grave consequences including explosions that put people’s lives in danger, as well as supply interruptions, resource waste, and pollution. Pipes are prone to damage because of corrosion, fractures, and mechanical damage, resulting in a productivity decrease due to the accumulation of deposits, corrosion, and mechanical impurities. Industrial pipelines are made up of materials like stainless steel and mild steel; hence, they are more prone to degradation over time, and it is common to have problems like loss of metal and corrosion, leading to pipe cracks, bursting, and deformations. Pipelines used in the industrial sector vary in size from millimeters to meters, having complicated shapes and branches like T-shape and Y-shape, making cleaning more difficult. Hence, using automated devices for inspection and cleaning operations is a better solution.

Moreover, firearms including small arms and large caliber tanks and artillery guns are made of heavy-duty steel alloys and undergo immense pressure once the projectiles are fired. The upkeep and reliability of these barrels is important with the precision once the firing takes place. The right condition of barrel has significant effect on the accuracy, range, and effectiveness of fire. The idea has been to develop an automatic mechanism that can keep the barrels maintenance easy for the operators for allowing larger life to the barrels in parallel improve the effectiveness of fire.

The Need for Innovation

There are serious problems with the manual cleaning process of small calibers and multiply for the large calibers because this requires laborious effort in disassembly, cleaning and assembling it again. The manual process is not tiresome but also inconsistent and impossible for the depth areas to access. The proposed automatic robotic bore cleaning can be taken as a simple solution that not only automates the process but makes it simplistic and fun to do.

How it Works

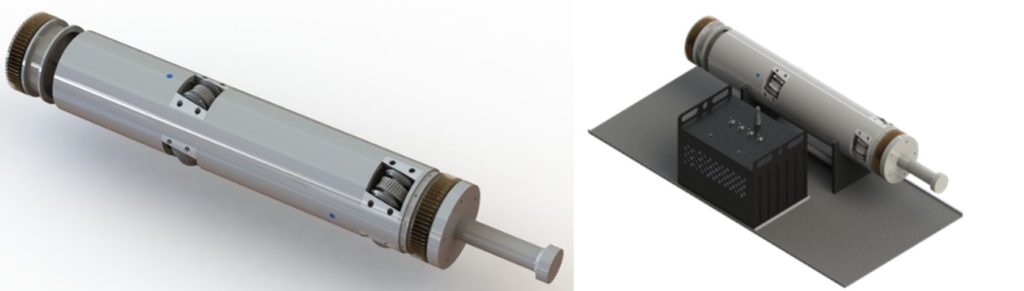

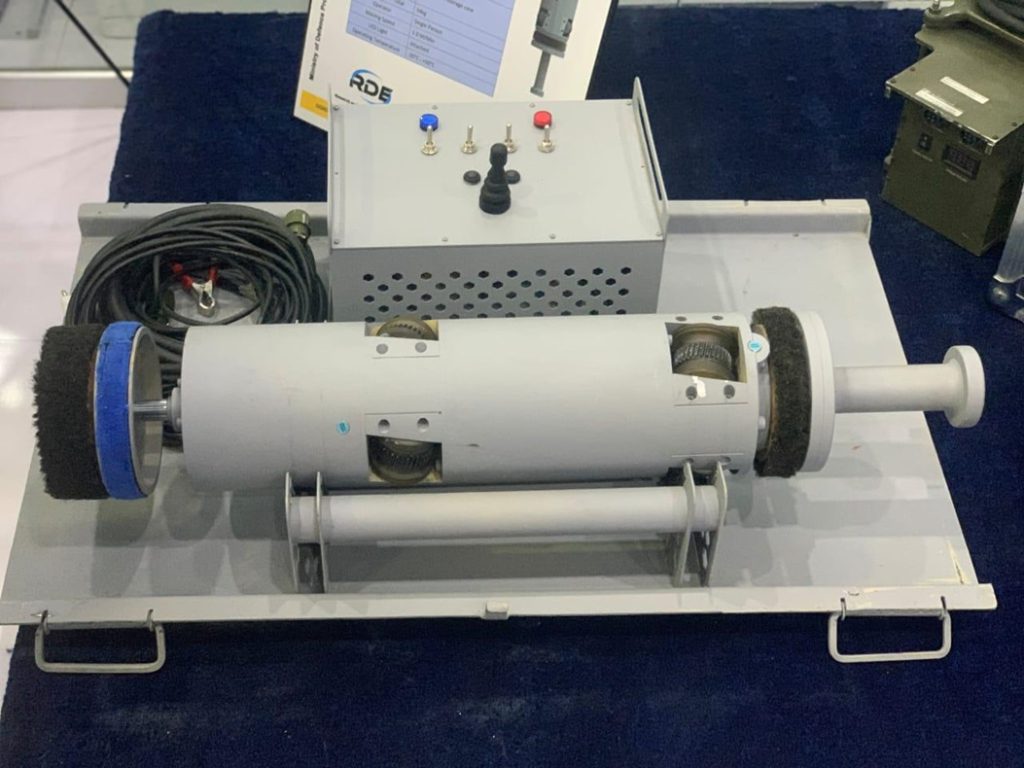

The Munazzaf is an easy-to-use apparatus that is designed with state-of-the-art electronics supported with appropriate control strategies while keeping the goal of effective and consistent cleaning in mind. The damage to the barrel is avoided by suitable combination of hard and soft wired brushes and approved cleaning solvents. A smart control console is used by the operator to channelize the robotic movement within desired caliber pipes and barrels. The movement can be switched between fully automatic or manual as per desire based on condition and cleaning requirements. The system integrates metallic proximity sensors to allow continued motion of the robot throughout the barrel in forward and backward direction. The process is repeated as many times as desired to ensure efficient cleaning in the minimum possible time.

Benefits of Automatic Pipes and Conduits Cleaning Robots

1. Time Efficiency

The Munazzaf successfully ensures effective cleaning with minimum effort in reduced time. The classical methods may sometime need to disassemble certain parts, carrying out cleaning and then assembling again which may consume considerable time and manual labor. Whereas the proposed robotic cleaner eases out the process in a quick way.

2. Precision Cleaning

The second advantage by use of the Munazzaf is precise cleaning in a consistent manner. It can clean areas that are difficult to reach for humans. Uniform cleaning is expected to enhance the life of pipes and barrels by avoiding rusty residues in non-accessible areas.

3. Consistency

Very importantly once a system deploys cleaning method in a singular fashion throughout the pipe and barrel then it brings uniformity in the maintenance process. This minimizes human error by executing the process with similar precision thus ensuring consistency.

4. User-Friendly Operation

We have ensured that the control console is simple enough to be easy to use even for a child. Even individuals with limited technical expertise can operate robots effectively. This accessibility encourages regular and proper maintenance, promoting overall pipe and barrel safety and longevity.

5. Cost Savings

While the initial investment in an automatic gun barrel cleaning robot may seem significant, the long-term cost savings are notable. Regular and thorough cleaning reduces the risk of malfunctions and extends the life of the pipe and barrels, minimizing the need for costly repairs or replacements.

6. Operations

The automatic robotic cleaner can thoroughly clean the inside of the pipes and barrels as shown in Figure 3 and can be adapted to calibers from 120 to 210 mm (about 8.27 in). The robot can move inside the rifled pipes and barrels as well as smooth pipes and barrels. Its application is tested for military grid artillery guns and tanks for its efficacy. The product was recently presented at the KSA defense exhibition and has been delivered for maintenance of 155 mm (about 6.1 in) artillery guns at Tabuk and Taif in KSA. It has a large potential for export abroad due to compatible price tag vis-à-vis quality of the product against similar solutions.

Challenges and Future Developments

Despite the numerous benefits, automatic pipe and barrel cleaning robots are not without challenges. The initial cost of acquisition may be a barrier for some owners, and ongoing maintenance and updates could pose additional expenses. Moreover, as technology continues to evolve, ensuring compatibility with new cleaning methods and emerging barrel materials will be crucial.

We foresee incorporation of artificial intelligence, and laser scanner within the Munazzaf to allow evaluation of the barrel cleaning achieved and take decision at its own to continue the operation till a satisfactory level of barrel cleaning is achieved. The power requirement for the robot may be improved to work for longer hours on stand-alone batteries in case of power failures or battlefield condition. The machine can be made more compact and portable by reducing its weight further though microelectronics. The cleaning solvents with improved cleaning capability may also be selected.

Conclusion

We believe that the proposed solution for cleaning generous size barrels and pipes will change the thinking style of the users allowing them long life of their precious equipment thus saving huge money through avoiding failures. The solution being efficient yet cost effective will allow widespread adaptation of such robotic systems in military, industry, and commercial sectors. The innovative and convenient solution will not only enhance the barrel’s safety but also its performance with longevity.

The author is Professor and Director Academics at College of Electrical and Mechanical Engineering, National University of Sciences and Technology (NUST). He can be reached at imranshafi@ceme.nust.edu.pk.

Research Profile: https://bit.ly/3nEykpn

![]()