The industrial sector in Pakistan heavily relies on imported coal―a nonrenewable fossil source of energy―for its operations and power generation. Usage of coal as fuel incurs large import bills and leads to natural resources depletion, carbon emissions, and environmental pollution. Industries are therefore in need of alternate fuels, including waste-derived fuels, which are fuels produced from solid waste.

A few attempts have been previously made to explore municipal solid waste (MSW) derived fuels; however, certain problems hinder their widespread application. For example, if commingled MSW is used as the feedstock for fuel production, there are several problems, including presence of high moisture content (often greater than 60%), undesired impurities, dangerous contaminants, and lesser number of combustible fractions which accumulatively result into a low-quality fuel. Additionally, a sorting line must be installed for the separation of various waste components from the MSW which increases the land area requirement, technical complexity, and costs of the endeavor. Alternatively, while agricultural residues are abundantly available in Pakistan, they have relatively lesser fixed carbon content, higher ash content, lesser energy content (calorific value), and often involve considerable farm-to-industry transportation, making them less attractive to be used as fuel. Another example is tire-derived fuels, but their harmful environmental emissions restrict their usage.

Meanwhile, mismanagement of huge amounts of solid waste in the country is already causing environmental degradation, public nuisance, and health problems. In short, energy crisis (and associated reliance on fossil fuels) and mismanagement of solid waste are not just damaging national economy and negatively impacting society but also deteriorating environment and accelerating climate change.

In view of the above issues, an innovative strategy was conceptualized and verified — by a team of NUST’s researchers comprising Dr. Musharib Khan (principal investigator) and three BE Environmental Engineering final year students, i.e., Syed Aizaz Ali, Haniya Zainab Siddique, and Maham Nasir — to not just manage industrial solid waste but also utilize it as a renewable and indigenously available source of energy for on-site industrial applications (thereby eliminating the transportation need and associated costs). This research was a part of Pakistan Engineering Council (PEC) funded project titled, “Production and Testing of a Cleaner Waste-derived Solid Fuel for Industrial Applications”. The technical and environmental feasibility studies regarding the utilization of various solid waste streams resulting from an industry as renewable fuels for on-site energy generation were conducted. Because textile sector is one of the largest industrial sectors in Pakistan, it was selected as the case-study.

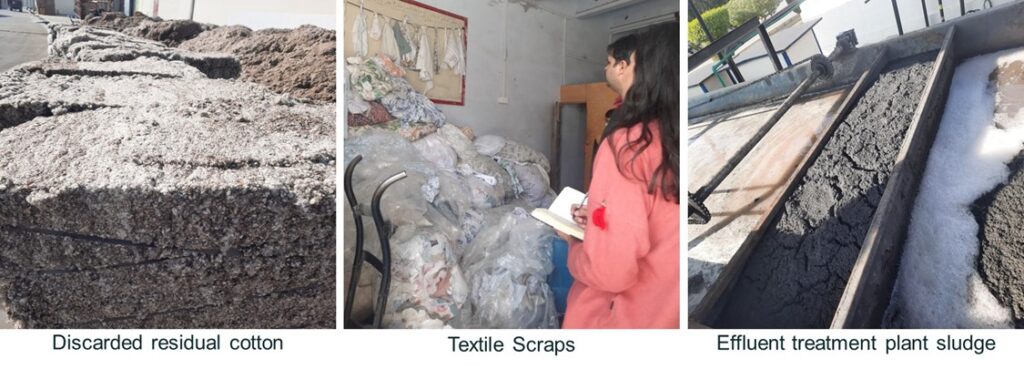

The major components of the study included identification and acquisition of various solid waste streams (types) generating in the textile industry; physical-chemical-thermal characterization of those waste types; preparation of different fuel samples through formulating mixtures of varying waste compositions; and analysis of flue gas emissions resulting from the combustion of those waste-derived fuel samples.

Through the survey of a local textile industry, textile scraps, residual cotton, cardboard, and effluent treatment plant sludge were identified as the major solid waste streams (Figure 1). From preliminary testing, sludge was found to have excessive moisture content and was thus excluded from further studies.

For a solid fuel sample, an energy content value greater than 15 MJ/kg is considered satisfactory. From the bomb calorimetric testing, the energy content of all the fuel samples was found to be greater than 16 MJ/kg and thus sufficient. The proximate compositional analysis revealed that moisture content of all the samples was less than 10% which is beneficial as otherwise higher moisture content of a material renders it unsuitable for combustion applications. The ash content of all samples was also found to be equal to or less than 10% which is also satisfactory because greater values of ash content imply operational difficulties particularly related to its continuous removal from the combustion chamber. The ultimate compositional analysis revealed that sulfur content in the samples was negligible which is a beneficial feature because presence of higher amounts of sulfur in the fuels leads to release of sulfur dioxide which subsequently causes acid rain. From flue gas analysis, it was found that SOx emissions were negligible, CO emissions were significantly less than coal, and NOx emissions were greater than that of coal but significantly less than the national environmental quality standards (NEQS).

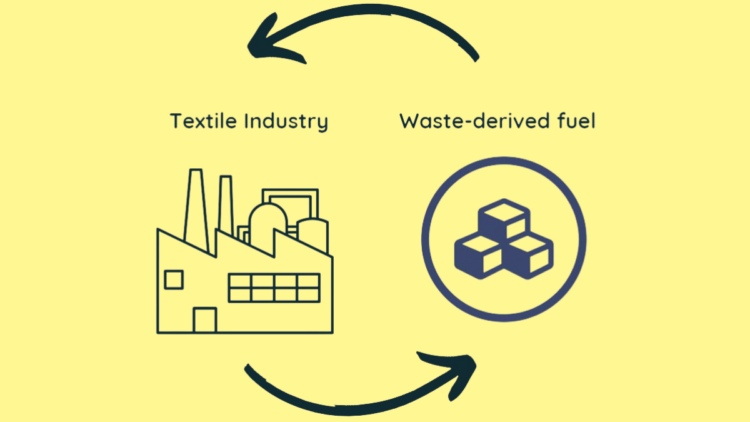

Overall, it was found that industrial solid waste resulting from textile sector could be utilized as an affordable and indigenously available fuel to meet on-site energy demands, and its performance could be even further optimized as needed through easily tweaking the relative proportion of ingredients, to obtain a fuel having least environmental damage. The project is aligned with UN’s Sustainable Development Goal – SDG 7 (Affordable and Clean Energy) and contributes towards sustainable solid waste management and its valorization into a renewable resource of energy as an alternate to fossil coal.

The author is Assistant Professor at the Institute of Environmental Sciences and Engineering (IESE), School of Civil & Environmental Engineering (SCEE), National University of Sciences & Technology (NUST), Islamabad, Pakistan. He can be reached at musharib@iese.nust.edu.pk.

Research Profile: https://bit.ly/4fbBm9C

![]()