Introduction

As the world shifts towards sustainable energy sources, researchers are constantly seeking innovative solutions to reduce our reliance on fossil fuels. In a groundbreaking study, scientists have developed a novel catalyst that converts waste cooking oil into biodiesel, paving the way for a cleaner, greener future.

Biodiesel production from waste cooking oil (WCO) has gained significant attention in recent years due to its potential to reduce greenhouse gas emissions and dependence on fossil fuels. However, the production process requires efficient catalysts to improve reaction rates and yields. Hydrochar, a carbon-rich material synthesized from waste biomass, has shown promise as a catalyst support. This study investigates the synthesis of novel transition metal loaded hydrochar catalysts from rice husk and their application in biodiesel production using WCO.

The Problem: Waste Cooking Oil

Waste cooking oil (WCO) is a significant environmental concern. If not disposed of properly, it can contaminate soil and waterways, harming ecosystems and human health. Converting WCO into biodiesel offers a sustainable solution, reducing waste and greenhouse gas emissions.

The Solution: Transition Metal Loaded Hydrochar Catalyst

Researchers have created a novel catalyst by loading transition metals onto hydrochar, a carbon-rich material synthesized from rice husk waste biomass. This innovative catalyst has shown remarkable efficiency in converting WCO into biodiesel.

How it Works

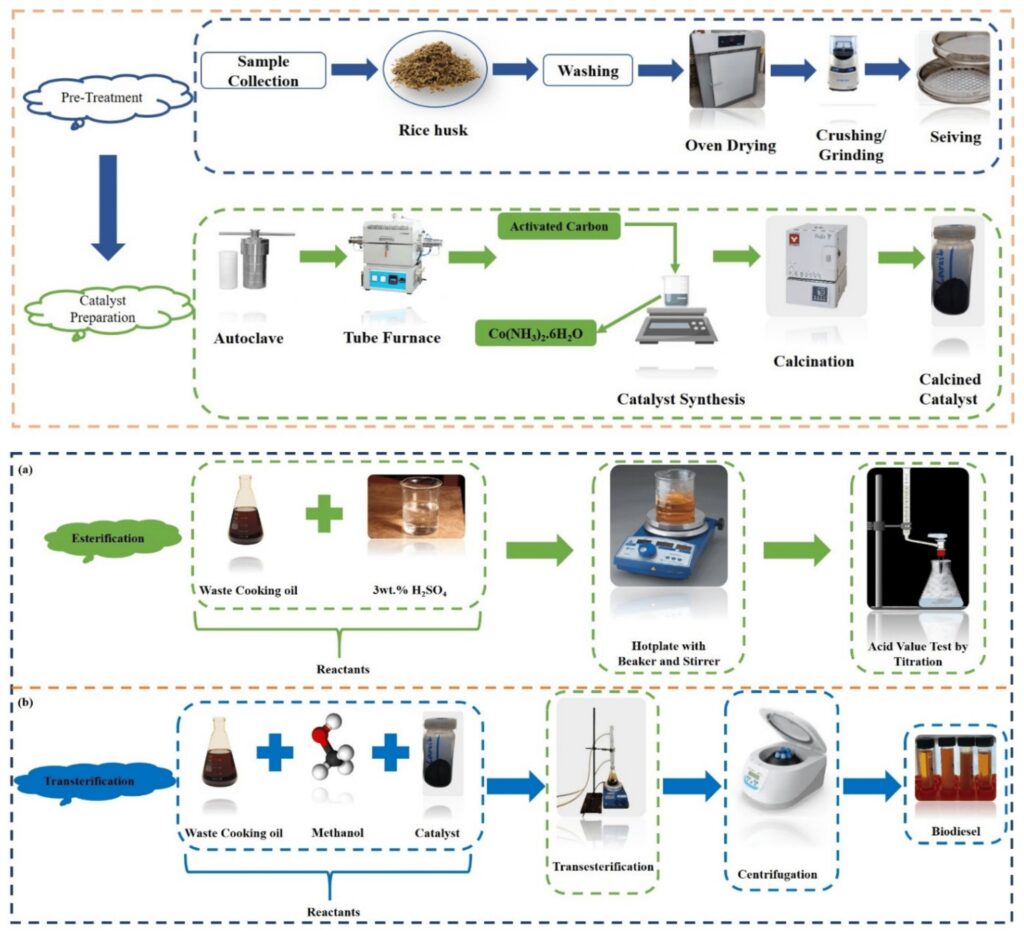

Synthesis of Hydrochar Catalyst

Rice husk, a lignocellulosic biomass, is rich in silica and carbon. Hydrochar can be synthesized through hydrothermal carbonization (HTC) of rice husk. HTC involves heating the rice husk in water at high temperatures (150-250°C) and pressures, resulting in a carbon-rich material.

Characteristics of Hydrochar Catalyst

The hydrochar catalyst derived from rice husk possesses several desirable properties:

- High surface area: Hydrochar has a high surface area, which enables better interaction with reactants.

- Acidic and basic sites: Hydrochar contains both acidic and basic sites, making it an effective catalyst for various reactions.

- Thermal stability: Hydrochar exhibits high thermal stability, allowing it to withstand high temperatures during catalytic reactions.

Application in Biodiesel Production

The hydrochar catalyst can be used in the transesterification reaction of waste cooking oil to produce biodiesel. The catalyst:

- Enhances reaction rate: Hydrochar catalyst accelerates the transesterification reaction, resulting in higher biodiesel yields.

- Improves fuel quality: The catalyst helps to reduce the acidity and viscosity of the biodiesel, making it a better-quality fuel.

- Reduces catalyst cost: Using hydrochar as a catalyst can reduce the overall cost of biodiesel production, making it more economically viable.

Benefits of Using Waste Cooking Oil

Using waste cooking oil as a feedstock for biodiesel production offers several advantages:

- Renewable energy source: Waste cooking oil is a renewable energy source, reducing dependence on fossil fuels.

- Waste reduction: Converting waste cooking oil into biodiesel reduces the amount of waste disposed of in landfills.

- Lower greenhouse gas emissions: Biodiesel produced from waste cooking oil can reduce greenhouse gas emissions compared to traditional fossil fuels.

Materials and Methods

- Rice husk was used as the waste biomass precursor for hydrochar synthesis.

- Transition metals (Cu, Ni, Co, and Fe) were loaded onto the hydrochar support using impregnation methods.

- The catalysts were characterized using techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy-dispersive spectroscopy (EDS).

- Biodiesel production was carried out using WCO and methanol, with the transition metal loaded hydrochar catalysts.

Results and Discussion

- The hydrochar catalysts exhibited high surface areas and pore volumes, making them suitable for catalytic applications.

- The transition metal loading significantly improved the catalytic activity, with Cu-loaded hydrochar showing the highest biodiesel yield (92.5%).

- The catalysts showed good reusability, with minimal loss of activity after five cycles.

- The biodiesel produced met the ASTM standards for fuel quality.

Conclusion

This study demonstrates the potential of novel transition metal loaded hydrochar catalysts synthesized from waste biomass (rice husk) for biodiesel production using WCO. The catalysts showed high activity, reusability, and fuel quality, making them a promising alternative to conventional catalysts. Further research is needed to scale up the catalyst synthesis and optimize the biodiesel production process.

Recommendations

- Investigate the use of other waste biomass precursors for hydrochar synthesis.

- Optimize the transition metal loading and catalyst synthesis conditions.

- Scale up the catalyst synthesis and biodiesel production process.

- Investigate the use of hydrochar catalysts for other catalytic applications.

Benefits

- Renewable Energy Source: Biodiesel produced from WCO reduces our reliance on fossil fuels and lowers greenhouse gas emissions.

- Waste Reduction: Converting WCO into biodiesel minimizes waste and prevents environmental pollution.

- Cost-Effective: The novel catalyst is synthesized from waste biomass, reducing production costs and making biodiesel more economically viable.

The author author is an Associate Professor at U.S.-Pakistan Center for Advanced Studies in Energy, National University of Sciences and Technology (NUST). He can be reached at rabia@uspcase.nust.edu.pk.

![]()