Microelectromechanical Systems (MEMS) refer to a group of batch fabricated devices at the sub-millimeter scale that use both mechanical and electrical components to perform sensing, actuating and storage functionalities. The small size of MEMS devices make them attractive for various applications like micro magnetometers, micro gyroscopes and RF MEMS in the aerospace industry, micro pressure sensors and micro accelerometers in the automotive industry, micro-mirrors in the biomedical industry, energy harvesters in the energy efficient systems, micro tunable filters in the communication industry, and micro scanning probes in the data storage industry. MEMS are considered as enabling technology for the emerging technologies including nanotechnology, robotics, internet of things (IoTs) and smart industry (Industry 4.0). The global MEMS market is expected to increase to USD 31 Billion by year 2023, with Compound Annual Growth Rate (CAGR) of 17.5%, with increasing applications in consumer, automotive, industrial, medical, aerospace and telecommunications industry.

MEMS inertial sensors are electromechanical devices at the microscale that offer high precision and compact size as compared to the conventional sensors at the macroscale. The MEMS inertial sensors have their applications in the field of automotive, consumer products, and most importantly in the military and aerospace industry. The high-grade MEMS inertial sensors for applications like rocket guidance, platform stabilization, missile guidance and drone operations are critical requirements of the defense industry. For the consumer and automobile applications, off the shelf low grade MEMS inertial sensors are easily available in the market. However, for the defense and aerospace industry, with the requirement of high precision and reliability, tactical and navigation grade MEMS inertial sensors are required which exponentially increases their cost and are also under strict export laws of the technologically advanced countries.

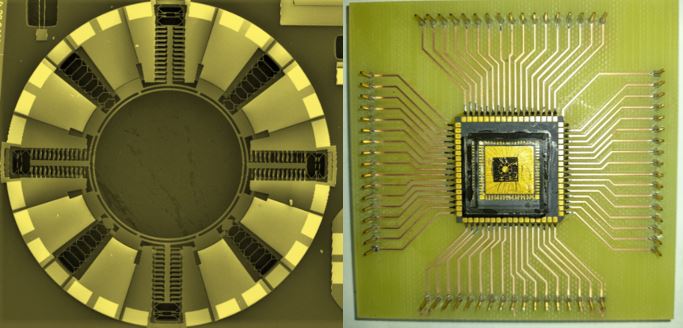

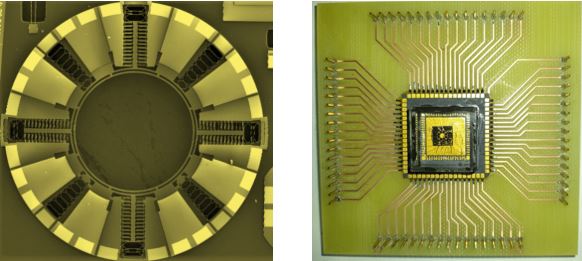

Navigation grade MEMS inertial sensors have been developed by the researchers from College of Electrical and Mechanical Engineering (College of E&ME) for the local defense industry with funding from Higher Education Commission – Technology Development Fund (HEC – TDF) grant. The MEMS inertial sensors are developed using commercially viable fabless manufacturing approach i.e. with in-house design using state-of-the-art MEMS design software CoventorWare and fabrication using the low cost multi-project-wafer (MPW) process SOIMUMPs, offered by MEMSCAP Inc. USA. The developed inertial sensors include MEMS accelerometers and gyroscopes and meet the critical performance requirements for different applications, including low bias drift and operating temperature range of −40 ᵒC to 100 ᵒC.

The project team includes faculty members; Dr. Muhammad Mubasher Saleem (Assistant Professor) and Dr. Amir Hamza (Assistant Professor) from Department of Mechatronics Engineering, NUST College of E&ME. The team is working in close collaboration with the local industry and has licensed 02x intellectual property rights of MEMS inertial sensors to the industry.

For more technical details of the developed MEMS inertial sensors and related research work by the project team, please visit www.memestech.com.pk.

The author is an Assistant Professor at the College of Electrical and Mechanical Engineering (CEME), National University of Sciences and Technology (NUST). He can be reached at mubasher.saleem@ceme.nust.edu.pk.

His research profile can be reached at https://scholar.google.com/citations?hl=en&user=TgNzK9YAAAAJ