Manufacturing industries have an important role in sustainable economic development. In order to expand and continuous improvement in the manufacturing industry, attention should be given to the sustainability of resources that the industry consumes. Manufacturing industries are embracing new strategies and concepts to overcome the deficiency of resources required to manage their daily operations. These industries are concentrating on accomplishing sustainability in each process of their production, from resource consumption to the reusing of waste. Therefore, the importance of incorporating sustainable energy systems and water and environmental conservation is necessary for industrial sustainability.

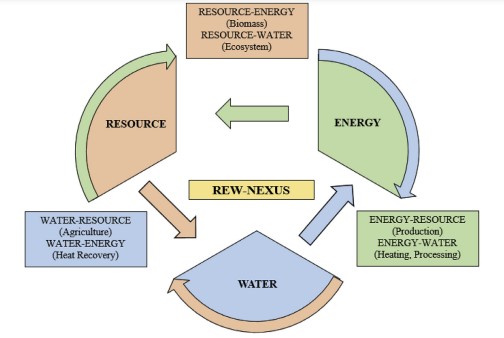

Dr. Shahbaz Abbas, Department of Engineering Management, CEME, has developed a fundamental resource-energy-water (REW) nexus as an integrated model for the Pakistani printing textile factories as shown in the Figure 1. The objective of the research significantly follows the SDG No 12 i.e. Responsible Consumption and Production. The model has been validated using system dynamics analysis. The REW nexus is the first nexus of its kind that can be adopted by most of the other manufacturing industries to manage their resources, energy, and water in a sustainable way.

This study uses a system dynamics approach to illustrate the interaction between energy and water in the case of the textile industry in Pakistan, and is intended to maximize resource efficiency. According to Fig. 1, the resource-energy interaction indicates that the waste of the resource, which is cotton crop waste, can be utilized as biomass energy and the resource-water interaction indicates that the agricultural products and water determines an association with the eco-system. The energy-resource interaction shows that an extensive amount of energy is required to process and produce the yarn/fabric by the process of spinning and weaving. The energy-water interaction shows that energy is required to heat, boil, and process the water during the textile industrial process. The water-resource interaction indicates that water is crucial for the agricultural sector as the cotton resource is an agricultural product. The water-energy interaction is based on the fact that wastewater from the textile process can be used as a source of energy in a textile factory after a heat recovery process. This water can also be reused in the industrial process.

The previous available models address strategies to manage sustainability issues and reduce carbon footprints. However, they do not sufficiently emphasize the importance of managing resource, energy, and water requirements, particularly for the textile industries. The REW nexus is the first nexus of its kind that can be adopted by the textile factories to manage their resources, energy, and water in a sustainable way.

The previous available models address strategies to manage sustainability issues and reduce carbon footprints. However, they do not sufficiently emphasize the importance of managing resource, energy, and water requirements, particularly for the textile industries. The REW nexus is the first nexus of its kind that can be adopted by the textile factories to manage their resources, energy, and water in a sustainable way.

The nexus proposed in this study addresses the most appropriate options for the sustainability of the textile industry’s resources, energy, and water by analyzing the relationships between them. The two-way relationships between resources, energy, and water emphasize the implementation of renewable energy and wastewater treatment technologies to make each factory more self-sufficient and manage its daily production.

Concluding Remarks

Textile supply chain is connected with the agriculture, energy, and water sectors and consume a substantial quantity of these resources. The production targets of the textile industries cannot be compromised, as they are not only the backbone of the Pakistani economy but also a source of earnings for thousands of associated factory workers and farmers. The unexpected and extreme weather conditions have impacted the depletion of natural resource, which will have an adverse effect on industries. The developed REW nexus strongly comprehends to safeguard the production targets by practicing the reuse of resource, energy and water ensuring the cleaner and sustainable production.

Reference

Abbas S, Chiang Hsieh LH, Techato K, Taweekun J. Sustainable production using a resource-energy-water nexus for the Pakistani textile industry. S. Abbas, L.-H. Chiang Hsieh and K. Techato J Clean Prod 2020;271:122633. https://doi.org/10.1016/j.jclepro.2020.122633.

The author is an Assistant Professor at College of Electrical and Mechanical Engineering (CEME), National University of Sciences and Technology (NUST). He can be reached at s.abbas@ceme.nust.edu.pk.

Researcher’s Profile: https://bit.ly/3xT7hJN