Pakistan’s climate, characterized by long, hot summers that stretch over eight months, poses a significant challenge for maintaining comfortable living environments. With over 50% of electricity consumption attributed to residential buildings and the energy demand rising at 4% annually, the reliance on air conditioning systems to cool buildings leads to skyrocketing energy demands. According to the National Energy Efficiency and Conservation Action Plan (NEECAP) 2023-2030, improved energy efficiency measures in buildings can save up to 9 million tonnes of oil equivalent (Mtoe) of energy and reduce greenhouse gas emissions by 35 million tonnes of CO2 annually by 2030.

The building materials in Pakistan are characterized by low thermal resistance (R-value), which fails to provide adequate insulation against the external environment, resulting in significant energy loss. The Energy Conservation Building Code (ECBC) 2023 highlights that the average R-value for walls in traditional buildings is far below international standards, necessitating the adoption of innovative solutions such as Phase Change Materials (PCMs) and insulated panels.

Furthermore, the country faces an electricity shortfall of 6,000–7,000 MW during peak summer months, causing severe load shedding and pushing households and businesses to rely on inefficient diesel generators. This adds to the already high cost of energy, which accounts for nearly 40% of household expenditure in urban areas. The reliance on imported fuels for power generation further exacerbates the issue, contributing to volatile energy prices and a deteriorating balance of payments.

These challenges make it critical to explore sustainable and energy-efficient building solutions. Innovative materials like PCM-incorporated bricks, which regulate indoor temperatures and reduce reliance on HVAC systems, present an opportunity to address these pressing issues. Scaling up the adoption of such technologies is essential for reducing energy wastage, enhancing thermal comfort, and improving the resilience of the built environment to Pakistan’s harsh climate conditions.

Energy-Efficient Buildings

Energy-efficient buildings are designed to reduce heating and cooling costs while promoting sustainability. By minimizing the energy required to maintain indoor comfort, these buildings can significantly lower utility bills and reduce carbon emissions. One of the simplest ways to achieve this is through insulation, which creates a barrier to heat exchange between a building’s interior and the external environment. Effective insulation helps keep buildings cool during scorching summers and warm during cold winters, thus reducing the reliance on energy-intensive heating and cooling systems.

While heavier building materials can enhance insulation, they also drive-up construction costs, making them less feasible for widespread use. This has spurred researchers to explore advanced materials, with Phase Change Materials (PCMs) emerging as a promising solution which not only provide excellent thermal insulation but also store and release energy during phase transitions.

What Are Phase Change Materials (PCMs)?

PCMs are materials capable of storing and releasing large amounts of energy through phase changes, such as melting and solidifying. When exposed to heat, PCMs absorb it, remaining at their melting point until fully liquefied. When temperatures drop, these solidify and release stored heat. This unique property allows PCMs to stabilize indoor temperatures, improving comfort and reducing energy consumption. Incorporating PCMs into construction materials like bricks can transform traditional building practices, making homes and workplaces more sustainable, affordable, and resilient to climate challenges. Eutectic PCMs, a combination of two or more PCMs with distinct melting points, offer tailored thermal properties for specific applications. By carefully blending PCMs, their thermophysical properties can be optimized, enhancing their suitability for particular temperature ranges or environments.

Integrating PCMs in Building Materials

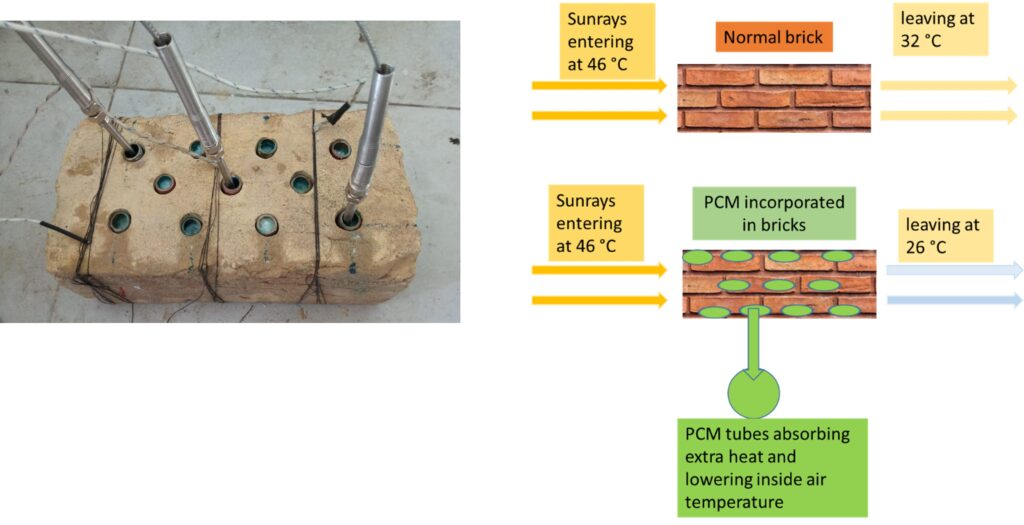

Recognizing the widespread use of clay bricks in Pakistan’s construction industry, this study explored the potential of PCM-incorporated bricks to improve thermal regulation in buildings. The idea was simple yet effective: trap excess heat in the PCM before it enters the building.

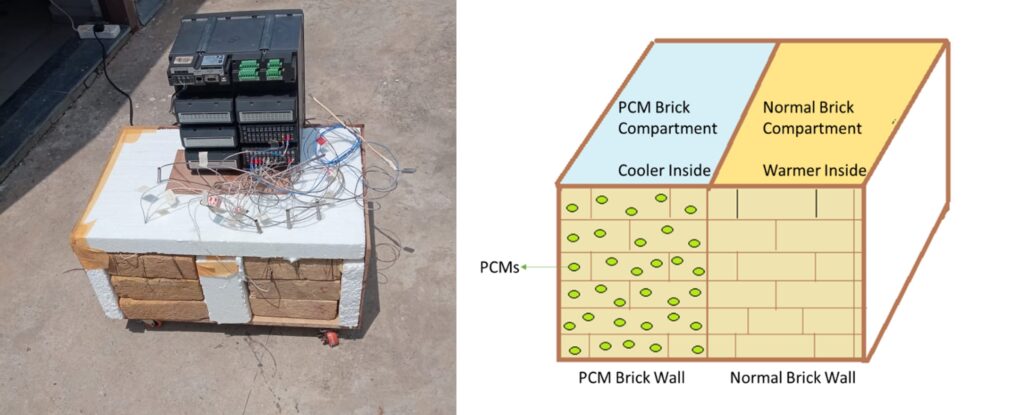

To test this concept, two identical compartments were constructed (Figure 1), one using regular clay bricks and the other with PCM-incorporated bricks (Figure 2). The experiment was conducted on the roof of a building at National University of Science and Technology(NUST), Islamabad during July and August, under peak summer conditions of 2023. The PCM used was a eutectic mixture of organic fatty acids (Lauric and Palmitic acids) with a melting point of 36.35°C and a latent heat capacity of 184.26 J/g.

Key Findings

Temperature Reduction

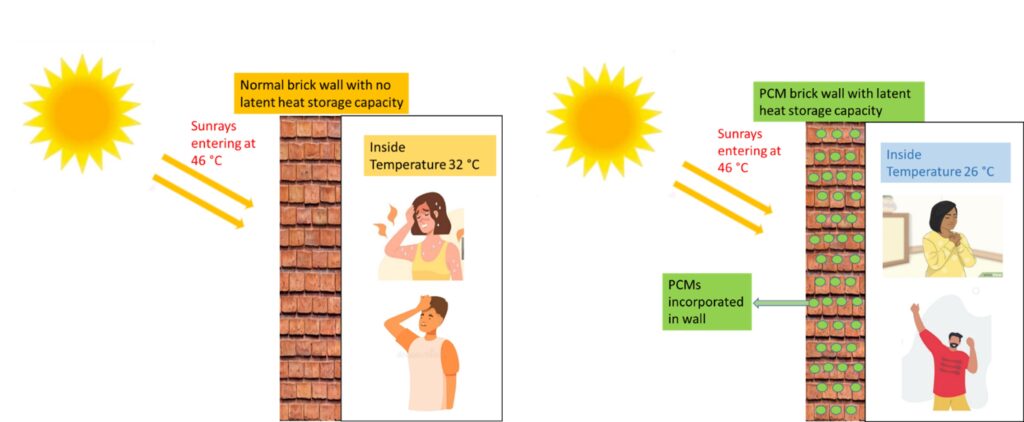

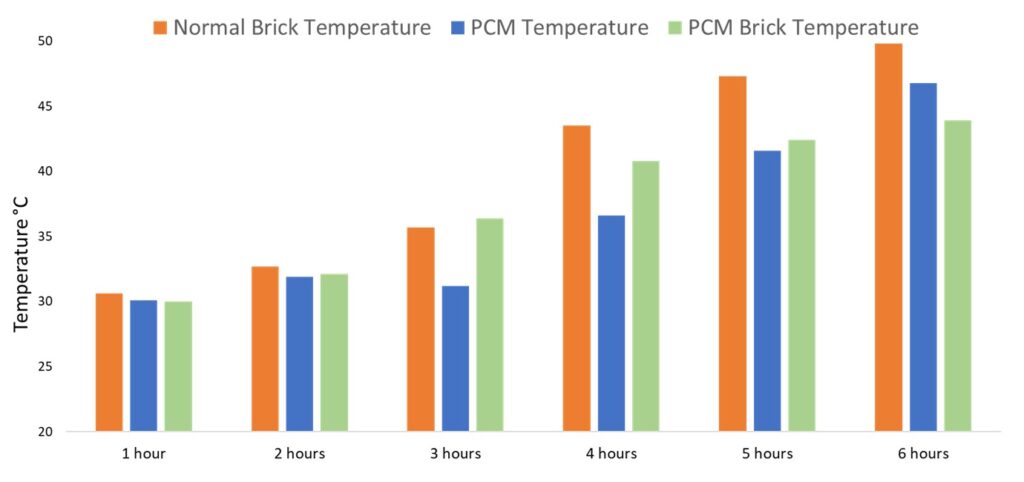

Data from the temperature results gathered revealed notable temperature differences (Figure 4) between the compartments. On July 24, 2023, with an ambient temperature peak of 53°C, the PCM compartment maintained a temperature 4.6°C lower than the regular brick compartment. Similarly, on August 8, 2023, the PCM compartment exhibited a peak temperature reduction of 5.5°C. This reduction was due to PCM absorbing excess heat during its melting process, delaying the rise in indoor temperature. These lower indoor temperatures not only enhance occupant comfort but also reduce the reliance on air conditioning, leading to significant energy savings and lower electricity bills.

Thermal Amplitude

Thermal amplitude refers to the variation in indoor temperature as it responds to outdoor temperature changes. Lower thermal amplitude indicates that indoor environments remain more stable, providing greater comfort to occupants and reducing the load on heating and cooling systems. On July 24, the PCM bricks reduced thermal amplitude by 32%, while on August 8, the reduction was 16%. This means that despite large temperature swings outdoors, the indoor environment remained more consistent, demonstrating the effectiveness of PCM bricks as thermal dampers. The temperature distribution depicted in graph below indicates that PCM brick ended with maximum temperature of approx. 42 degree Celsius whereas temperature for regular clay brick was around 49 degree Celsius at this point. This heat difference was retained by PCM incorporated whose temperature was approx. 45 degree Celsius. These results show that PCM bricks help in maintaining indoor comfort by absorbing excess heat during the day and releasing it when temperatures drop, making them particularly useful in regions with extreme temperature variations.

Energy Savings

Heat flux measures how much heat passes through the walls of a building. On August 8, the walls with PCM bricks reduced the amount of heat passing through by about 40 W per square meter compared to regular bricks. For an average house in Pakistan, this means that one wall with PCM bricks could save around 7 units of electricity (kWh) every hour during peak times. Over a full day, this adds up to about 18 units of electricity saved. This shows that PCM bricks can significantly reduce the energy needed for cooling, which can help lower electricity bills and reduce strain on the power grid during hot summer days.

Structural Integrity

To ensure that PCM bricks are strong enough for construction, a compression test was performed. This test measures how much weight a material can withstand before breaking. The PCM-incorporated bricks showed greater strength than regular clay bricks, supporting up to 117 kilo newtons (kN) of force compared to 90 kN for regular bricks. This increased strength is due to the use of copper capsules, which securely hold PCM and prevent leakage while adding durability to the bricks. This means PCM bricks not only improve energy efficiency by regulating indoor temperatures but also meet or exceed the strength requirements for use in buildings, making them a reliable and practical option for construction.

Implications and Future Directions

The integration of PCMs in building materials presents a cost-effective, sustainable solution to Pakistan’s energy crisis. By reducing the dependency on air conditioning, PCM bricks can lower energy consumption and greenhouse gas emissions while enhancing indoor comfort.

Scaling up this technology could greatly benefit the construction industry, especially in areas with very hot or cold climates. PCM bricks help maintain stable indoor temperatures by absorbing and releasing heat, which can reduce the need for air conditioning or heating. However, to make this technology more practical and affordable, further research is needed. For example, improving encapsulation techniques-the process of safely enclosing the PCMs to prevent leakage can make the bricks more durable and efficient. Additionally, reducing the production costs of PCM bricks will be key to making these affordable for widespread use, allowing more people to benefit from this innovative solution.

Conclusion

In conclusion, PCM-incorporated bricks provide a practical and impactful solution to address Pakistan’s energy challenges by enhancing indoor comfort and reducing electricity demand. By adopting such innovative materials in line with the NEECAP and the ECBC standards, we can significantly lower greenhouse gas emissions and achieve energy savings. This not only helps combat climate change but also alleviates the energy crisis, reducing electricity costs for households and improving living standards in the local community.

The author is an Assistant Professor, at Department of Mechanical Engineering, School of Mechanical Manufacturing Engineering (SMME), National University of Sciences and Technology (NUST). He can be reached at waqaskhalid@smme.nust.edu.pk.

![]()