Coronavirus disease the COVID-19 is a newly discovered infectious disease caused by a novel coronavirus. As the Covid-19 pandemic spread in the world, the public were introduced to the new living behaviors that previously unheard of, at least to the general populace. A collective, global effort was started in 2020 to combat, mitigate and control the spread of the disease. The medical sector established emergency centers for patients, the pharmaceutical industry started efforts towards making the vaccines, while the engineers started designing devices and instruments.

It is widely known that COVID-19 causes difficulty breathing or shortness of breath among other symptoms. Keeping in view the symptoms and difficulties the patients affected by this disease face, a team of engineers lead by Dr. Zafar Bangash of the College of Electrical and Mechanical Engineering (CEME), National University of Sciences & Technology (NUST) identified a key areas and started working on the design and development of an electro-mechanical ventilator in February 2020.

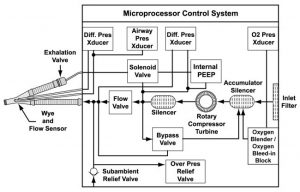

A ventilator is an electro-mechanical device that assists in breathing efforts of patients by moving breathable air into and out of the lungs, a schematic is shown in Figure. 2. Ventilators are a common life-saving equipment in the emergency departments of hospitals. Ventilators deliver a precise and measured quantity of air to the patient based on a defined strategy by the physician. The permutations can be a measured quantitatively via total volume, rate, or pressure.

As Covid-19 causes Acute Respiratory Distress Syndrome (ARDS), the lungs of the affected patients have to be treated with extreme precaution and care. As the oxygen absorbing capacity of the lungs get deteriorated, it becomes essential to provide excess oxygen to the patient by controlling the forced inhalation of oxygen level in the ventilator. Generally, ventilators are categorized as life-critical systems as any failure of ventilator may result in the loss of life of the patient.

While the mechanical ventilators have been built since 1940s, it was in 1982 that the first microprocessor based ventilator was released, which revolutionized the field by providing customized oxygen delivery as well as monitoring of the system. Current advancements in technology; namely low cost, easy to program microcontrollers; has made possible the design of very complex electro-mechanical systems such as a ventilator, in a short duration with limited resources.

In the late 2019 – early 2020, after a series of discussions between the experts from various medical and engineering groups, it was finalized to develop low cost, mass produce-able ventilator that can be used for patients requiring critical care, after contracting novel coronavirus, SARS-CoV-2. As a part of this project, a complete system was developed at a fast pace and was presented to the Pakistan Engineering Council (PEC) for the purpose of preliminary evaluation and approval in July 2020. The device designed as a part of this project can provide all the essential modes of ventilation, with precision control of oxygen level to patients.

With much needed research being conducted to bring out more information about COVID-19 and with due discussions with multiple stakeholders, necessary improvements were made to the system making it capable of intelligent control and feedback for autonomous operation and for use by paramedical staff.

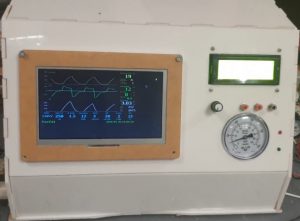

Several improvements in the device has made it possible for the system to include automated oxygen regulation for non-critical patients with lowered SPO2 levels in Continuous Positive Air Pressure (CPAP) and Bi-level Positive Air Pressure (BiPAP) modes, internal molecular sieve based oxygen generator and internal turbine for air delivery. The designed system is capable of operation without the requirement for any pressurized air or oxygen while providing the necessary respiratory assistance. Remote monitoring is also provided using WiFi and GPRS, making a revolutionary system that can be deployed at field-hospitals, ambulances and even domestically, at the homes of the patients. An image of the device is shown in Figure. 3.

Past couple of years has tested us all. The years gone by has seen families divided, conventional businesses collapsing with rising unemployment and hospitals near breaking point with so much suffering. These were tough years. But, we should remember these years not for the pain but for resilience so many of us showed; using hope, trust and faith as a guide. The author feels grateful to be able to use the knowledge and contribute to the Covid-19 relief efforts within Pakistan, with this project. Please wear a mask. Stay safe and optimistic.

Acknowledgements

The author is thankful to the Higher Education Commission (HEC), Pakistan for providing financial support for the project in form of the Technology Transfer Support Fund and to the parent institute CEME, NUST and Digital Pakistan Laboratory (DPL) for providing the support and facilities required in the design and development of the ventilator.

The author is an Assistant Professor at College of Electrical & Mechanical Engineering (CEME), National University of Sciences and Technology (NUST) and can be reached at zafar.bangash@ceme.nust.edu.pk.

Ventilators for Coronavirus, mechanical ventilation, Ventilators for Corona patients, coronavirus, coronavirus patients, low cost ventilators, low cost ventilators in Pakistani Market, ventilator price in Pakistan, low cost ventilator developed by NUST, low cost ventilators project, low-cost portable ventilators