Understanding Biohydrogen Production

Biohydrogen production refers to the generation of hydrogen gas through biological processes. This method is considered environmentally friendly compared to conventional hydrogen production methods that rely on fossil fuels. Among the various biological routes, dark fermentation and photo-fermentation are two key processes. Dark fermentation, typically performed by bacteria, produces hydrogen without the need for light, while photo-fermentation, often involving microalgae, requires light to generate hydrogen.

The Role of Microalgae and Bacteria

Microalgae like Chlorella vulgaris are known for their high photosynthetic efficiency and ability to produce biohydrogen under certain conditions. When combined with bacterial cultures, particularly those derived from wastewater activated sludge, the potential for hydrogen production increases significantly. Wastewater activated sludge contains a diverse microbial community capable of degrading organic matter and producing hydrogen as a byproduct.

The Two-Stage Immobilized Bioreactor: A Novel Approach

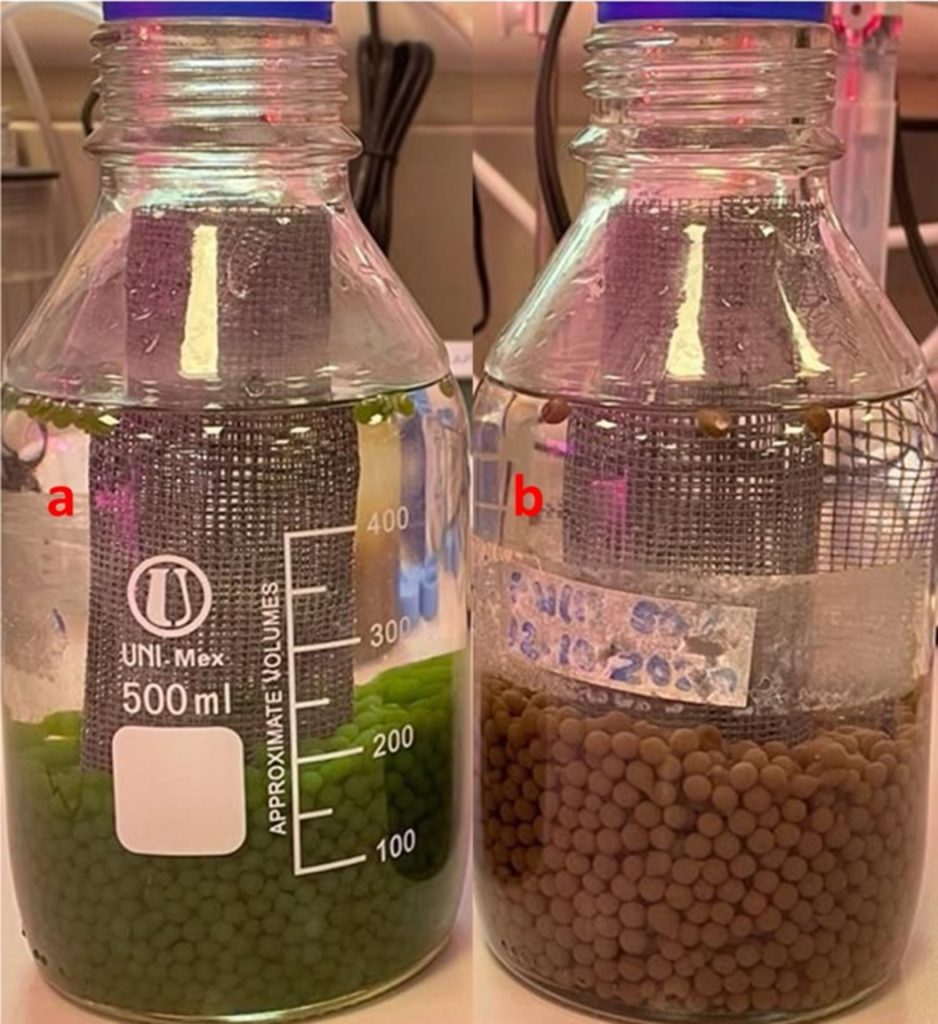

The novel two-stage immobilized bioreactor system was designed to integrate both dark fermentation and photo-fermentation processes, optimizing the conditions for maximum hydrogen production. Both microalgae and bacteria in wastewater activated sludge were immobilized in a novel way of configuration in separate chambers as shown in Figure 1. Here’s how it works:

1. First Chamber: Dark Fermentation

In the first stage, wastewater activated sludge is used to break down organic matter in the absence of light. This process generates hydrogen along with other byproducts such as organic acids. The use of immobilized bacterial cultures helps maintain a high cell density and stability, enhancing the efficiency of hydrogen production.

2. Second Chamber: Photo-Fermentation

The second stage involves the use of Chlorella vulgaris in a light-exposed environment. The microalgae utilize the organic acids produced in the first stage as substrates for further hydrogen production. The immobilization of microalgae ensures a stable and concentrated culture, facilitating continuous hydrogen generation.

Advantages of the Two-Stage System

The two-stage immobilized bioreactor offers several advantages over traditional single-stage systems:

1. Enhanced Hydrogen Yield

By combining dark fermentation and photo-fermentation, the system maximizes the utilization of organic substrates, leading to higher overall hydrogen yields.

2. Stability and Efficiency

Immobilization of both bacterial and microalgal cultures enhances the stability and efficiency of the bioreactor. Immobilized cells are less vulnerable to washout, allowing for longer operational periods and consistent hydrogen production.

3. Utilization of Wastewater

The use of wastewater activated sludge not only provides a rich microbial community but also contributes to waste treatment. This dual functionality makes the process economically and environmentally beneficial.

4. Reduction in Process Inhibitors (Byproducts)

The sequential use of organic acids from the first stage in the second stage reduces the accumulation of byproducts, streamlining the process and improving the purity of the hydrogen produced.

Challenges and Future Directions

While the novel two-stage immobilized bioreactor shows great promise, several challenges need to be addressed:

1. Optimization of Conditions

Optimizing the operational parameters, such as pH, temperature, and light intensity, and hydraulic retention time (HRT) is crucial for maximizing hydrogen production.

2. Scale-Up Potential

From lab-scale experiments to large scale experiments in a continuous flow presents significant challenges. Ensuring that the bioreactor performs efficiently at larger scales is essential for commercial viability.

3. Economic Viability

While the use of wastewater reduces feedstock costs, the overall economic feasibility of the system needs to be evaluated. This includes the costs associated with bioreactor construction, operation, and maintenance.

Conclusion

The development of a novel two-stage immobilized bioreactor for biohydrogen production using a partial microalgal-bacterial co-culture marks a significant advancement in renewable energy technology. By integrating both dark fermentation and photo-fermentation processes and immobilization, this innovative approach offers a promising pathway to sustainable hydrogen production. As research continues to optimize and scale up this technology, it has the potential to contribute significantly to the global transition towards clean and renewable energy sources.

Acknowledgment

The author at NUST would like to thank United Arab Emirates University (UAEU) for the funding and providing resources in conducting the research.

The author is a Assistant Professor at the School of Mechanical & Manufacturing Engineering (SMME), National University of Sciences and Technology (NUST), Islamabad – Pakistan. He can be contacted at asad.javed@smme.nust.edu.pk.

Research Profile: https://bit.ly/3zrAr5z

![]()