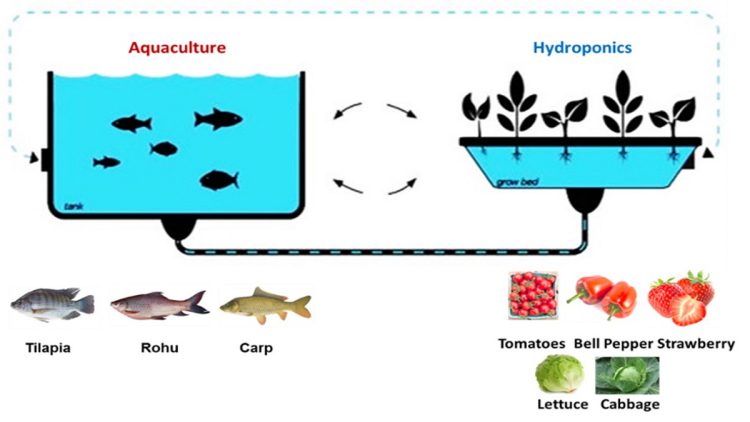

Pakistan is currently facing dire problems which requires serious attention such as the rapid increase in population i.e., 2% rise per year, with an estimate of 340 Million by 2050, 58% food insecurity, 1st in water shortage index among lower-middle income countries, drought in barani areas and a decrease in agricultural land use per capita. To address these problems, its important to pay special attention to the growth of agriculture sector which is the largest sector of Pakistan’s economy i.e., contributing 24% of the GDP. It is pertinent to mention that introducing new agriculture methods and connecting agriculture with technology i.e., Agri-tech can enhance the Pakistan’s economy. The aquaponics is one of such methods which integrates aquaculture (i.e. fish farming) and hydroponics (i.e. growing plants in a soilless medium) as shown in Fig. 1. Its primary objective is to provide an alternative to the traditional food production on industrial as well as private sectors. This system is particularly useful for urban areas with low land and overpopulation. The system requires minimal human interference during the cultivation process which results in increase in food production compared to traditional farming techniques. The final product of such method is purely organic (i.e. free from contaminants such as pesticides) and cheaper than traditionally grown crops. It uses 90% less water, grows six times more, has twice as fast yield and having all year-round organic production. The commonly used fish are tilapia, rohu and carp while the outcome include leafy vegetables and fruits such as cherry tomatoes, bell peppers, strawberries, lettuce and cabbage etc.

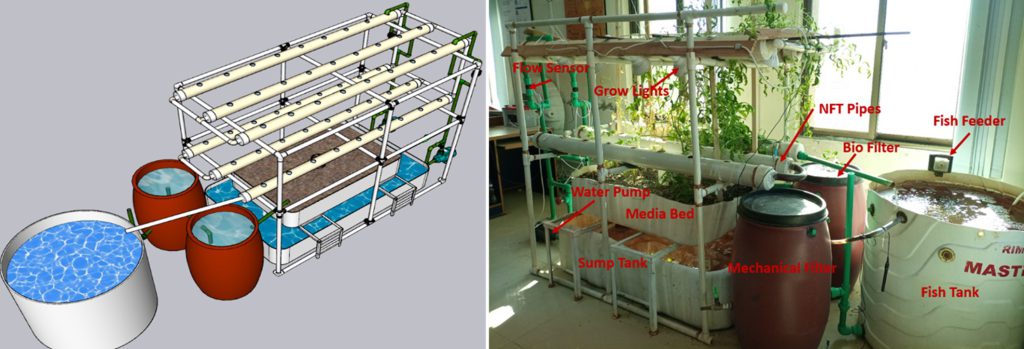

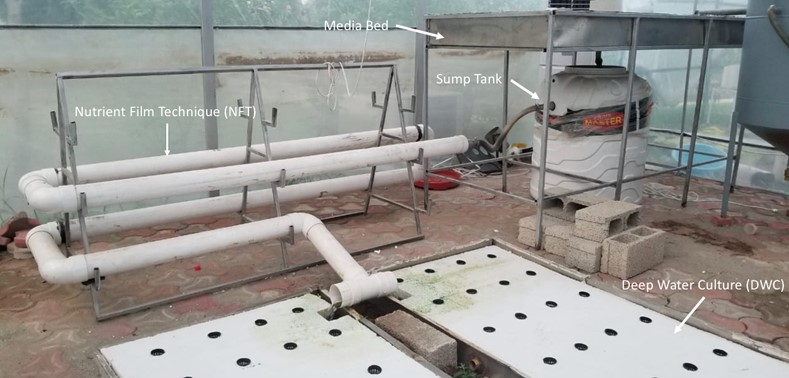

The aquaponics system employs different growing techniques such as nutrient film technique (NFT), media-bed and deep-water culture (DWC) to produce vegetables and fruits. The NFT and media-bed growing techniques can be used to grow fruits and vegetables while the DWC is typically used for light weight leafy vegetables.

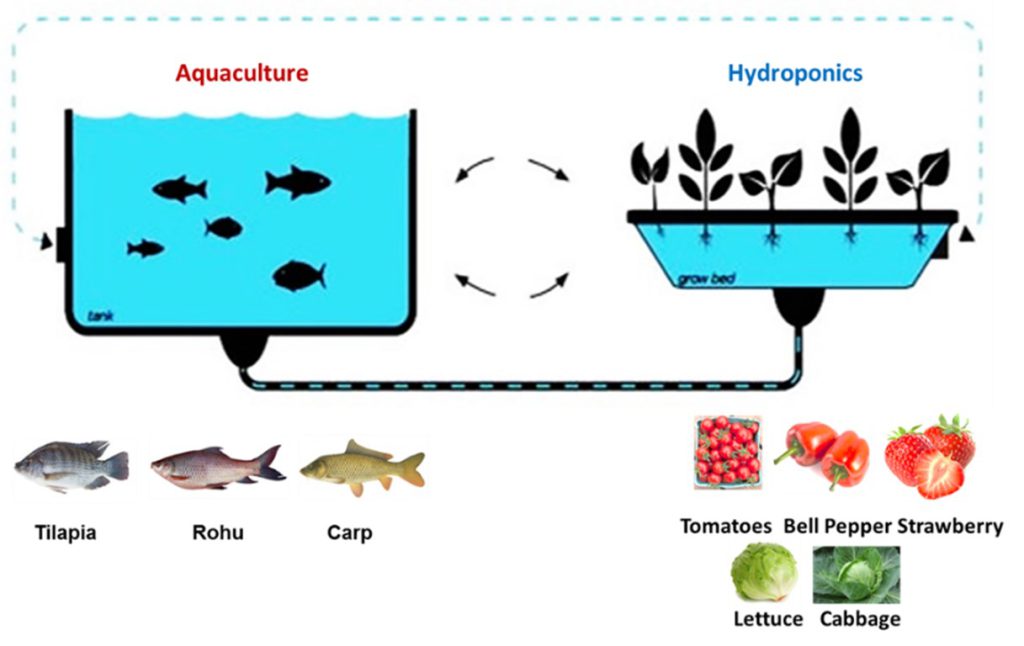

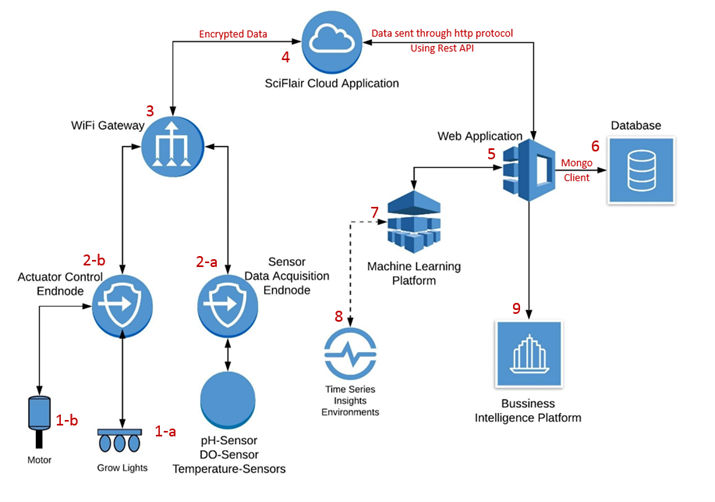

The aquaponics system can be made “smart aquaponics” by incorporating key technologies such as internet of things (IoT), machine learning (ML) and renewable energy (as shown in Figure 2) in order to make it an automatic and sustainable solution. The IoT devices can be used to monitor the chemical composition of water, temperature and humidity of the aquaponics farm remotely, while the ML can be used to optimize the growth of vegetables and fruits based on the nutrients data. The renewable energy sources like solar panels can be used to make the aquaponics farm sustainable in terms of power consumption.

The aquaponics technique is a matured agriculture method used worldwide such as in USA, Netherlands, China and Canada with an estimated market worth of USD $ 1.4 billion by 2025. In Pakistan, as per author’s survey, the focus is more on hydroponics (i.e., aquaponics minus fish) having in-organic produce. The hydroponics farms are located in several Pakistani cities including Faisalabad, Sialkot, Chakri and Lahore.

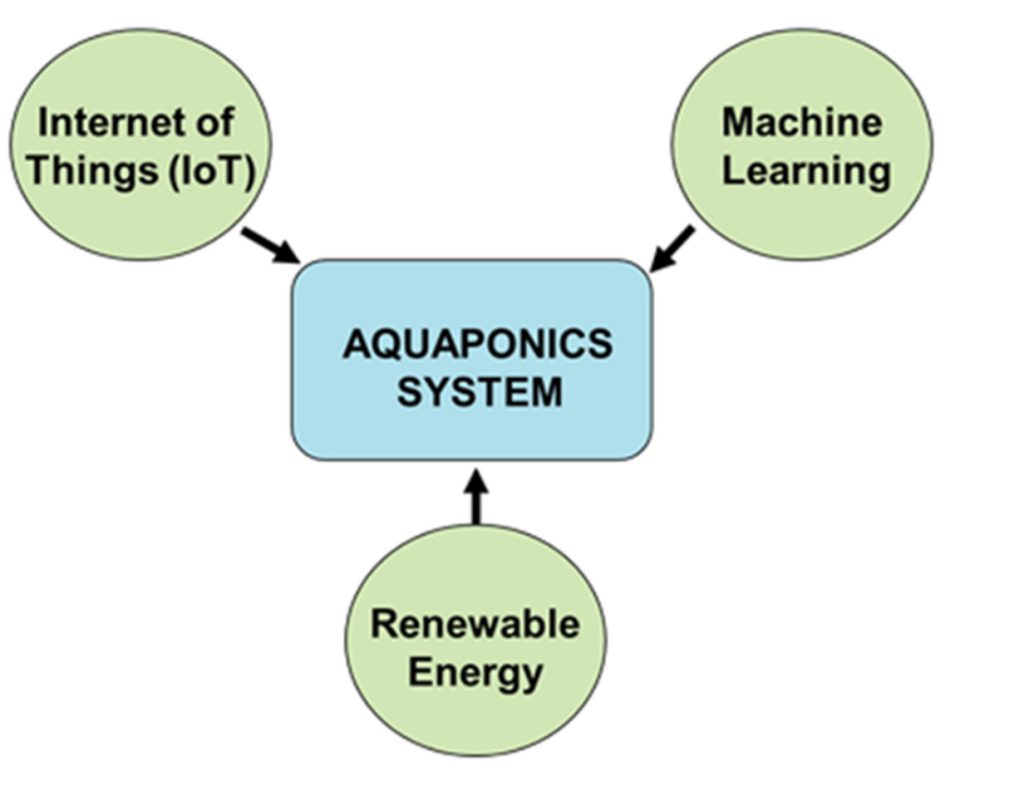

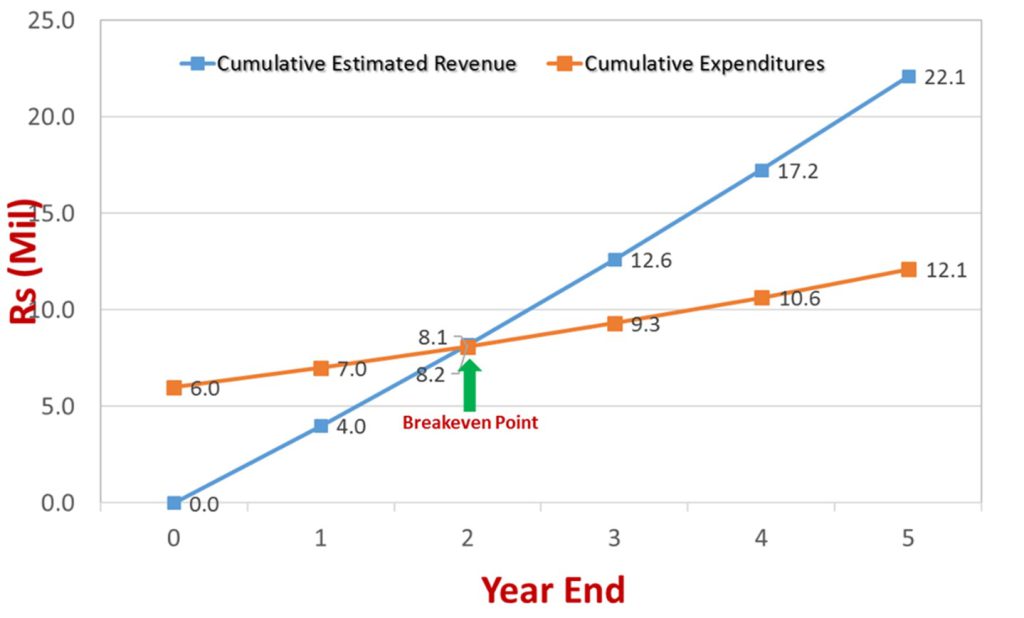

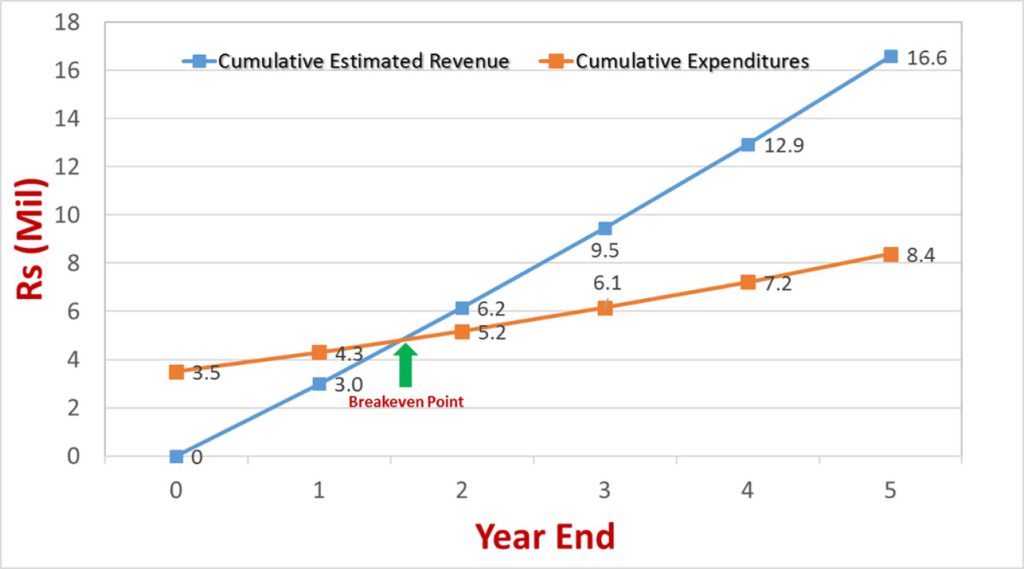

To understand the business viability from model farmer perspective, a breakeven analysis has been carried out. The following farm attributes have been considered for breakeven analysis:

- Farm Size: 10,000 sq. ft

- Produce: Bell pepper, Strawberry, Coriander, Lettuce

It can be observed from Figure 3 that with an initial investment of PKR 6 Million, the break-even point can be reached by 2nd year and a profit of PKR 10 Million over a period of 5 years can be achieved. It is expected that for large farm size the profit margin will be increased manifold. One the other hand, from the breakeven analysis of a similar size hydroponics farm, shown in Figure 4, it can be seen that with an initial investment of PKR 3.5 Million, the break-even point can be reached near 2nd year and a profit of PKR 8.2 Million over a period of 5 years can be achieved. This comparison of breakeven analysis concluded that both aquaponics and hydroponics techniques can be employed for growing vegetables and fruits and are profitable depending on the size of the farm.

During the execution of the project at NUST-SEECS, a comprehensive design analysis has been carried out and several test models of aquaponics systems have been developed. The integration of IoT network and web applications via cloud interface was also carried out. The IoT system collects the real-time data via several sensors while the Aquaponics Management System, which is a web-based platform developed for aquaponics farmers, can be used to smartly design, analyze, monitor, and control their aquaponics farms.

Initially, a lab prototype was developed as shown in Figure 4. This system employed NFT and media-bed growing techniques to grow tomatoes and bell-peppers. Afterwards, 120 sq. ft and 400 sq. ft outdoor aquaponics farms were constructed as shown in Figures 5-8. In these farms, the NFT, media-bed and DWC growing methods were used to grow the leafy vegetables and fruits including cherry tomatoes, bell pepper, strawberries and lettuce.

To make the aquaponics system “smart”, the integration of IoT network and web applications via cloud interface was also carried out. The IoT system collects the real-time data via several sensors. The basic layout of the IoT system in the aquaponics farm is shown in Figure 9; the system includes end nodes (2-a), for data acquisition from sensors and (2-b) for controlling the actuators i.e. motors and grow lights. The sensors used in the system are pH, Dissolved oxygen, and Temperature sensors; data is collected periodically from these sensors. The end nodes send data to the gateway (3) wirelessly, and then the encrypted data is then transmitted to the cloud server (4) using internet protocol. The web application (5) fetches data from cloud server using web hooks, and this data is stored in Database (6). This application (5) provides complete SCADA like monitoring of water parameters and allows the user to control actuators (water/air pumps and grow lights) installed in the system, provided the actuators are connected with the IOT end nodes. The machine learning platform (7) incorporates regression analysis and time series forecasting models, which are responsible for generating feasibility reports. The business intelligence (BI) tool is used for performing the data analytics.

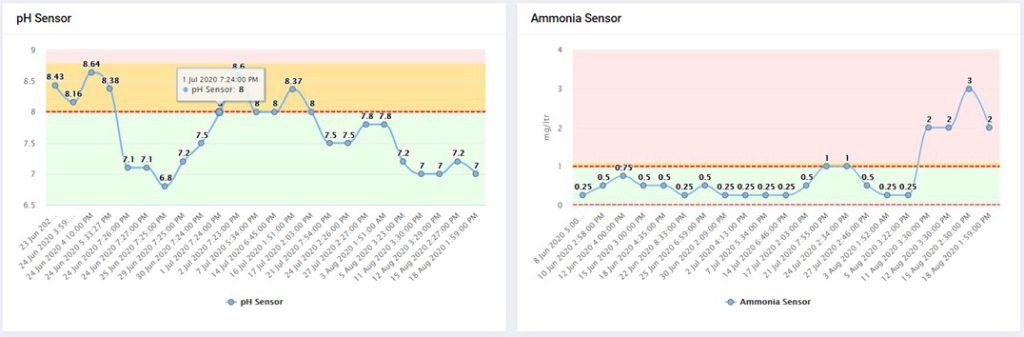

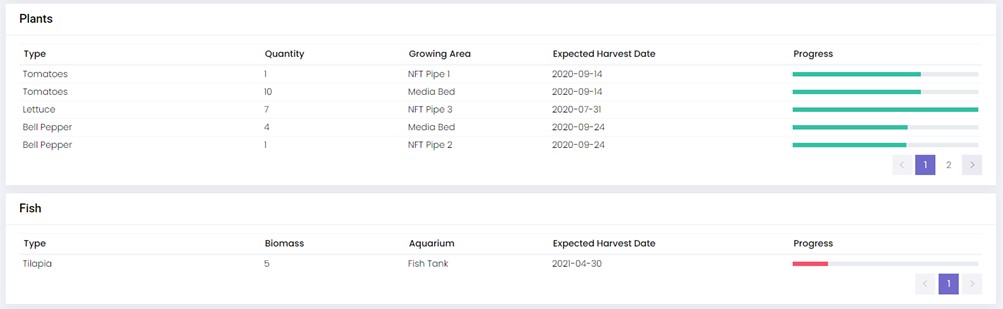

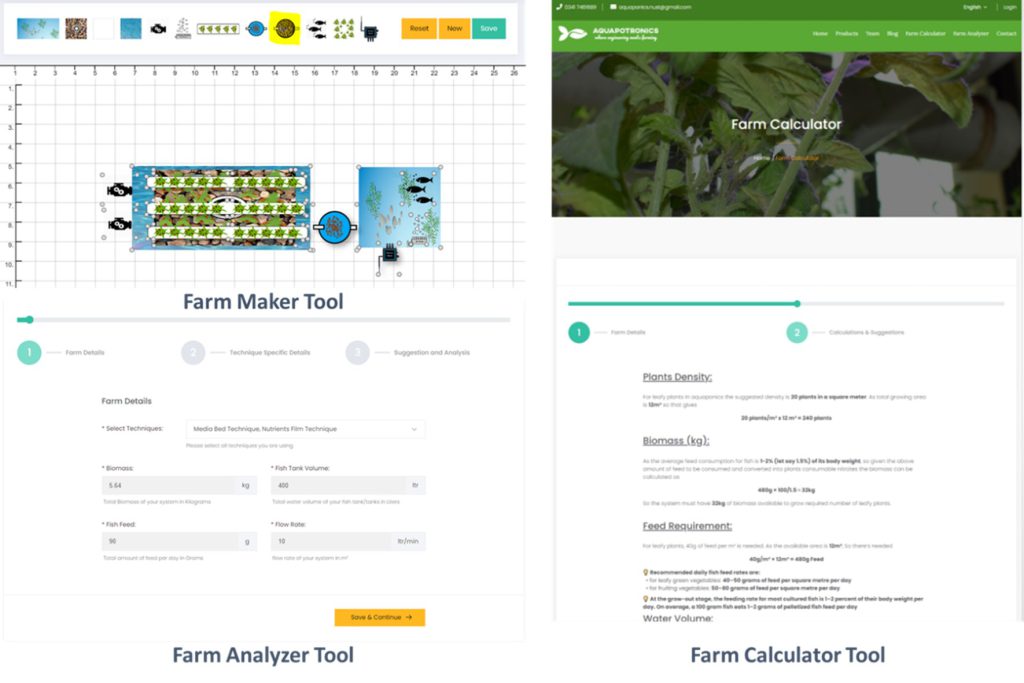

The Aquaponics Management System, a web-based platform, was developed for aquaponics farmers, which can be used to smartly design, analyze, monitor, and control their aquaponics farms. The sensor dashboard provides the real-time data of the sensors employed at various locations in the farm (as shown in Figure 10), while the plant & fish progress chart displays the expected harvest date for plants and fish as shown in Figure 11. The Farm Maker, Analyzer and Calculator Tools, shown in Figure 12, were also developed that can guide a user to develop and analyze an aquaponics farm.

In conclusion, it can be said that aquaponics is one of the key technologies that shall be adopted in Pakistan to address the local challenges. In addition to promotion of Agri-tech culture, our farmers shall be educated. The empowerment of farmers and acquaint them with new technologies is the dire need of the time. Such projects will not only contribute towards improvement of agricultural methods but also serve positively to the Pakistani society and economy.

Acknowledgment:

This work was funded through Higher Education Commission (HEC), Technology Development Fund (TDF), titled “An Automated Machine Learning Based Solar Powered Aquaponics System.”

The author is an Associate Professor at NUST School of Electrical Engineering and Computer Science (NUST-SEECS) can be reached at nosherwan.shoaib@seecs.edu.pk.

Researcher’s Profile: https://bit.ly/3Os5kbB