In Pakistan, there has been massive imports of electrical devices, piezoelectric actuators, car buzzers, and sensors to be used for several applications as they are not produced locally and these imports have burdened the national exchequer. Hence, we are in dire need of producing the piezoelectric powder in lab/pilot-scale locally and at affordable price in order to meet the requirements of affordable and clean energy.

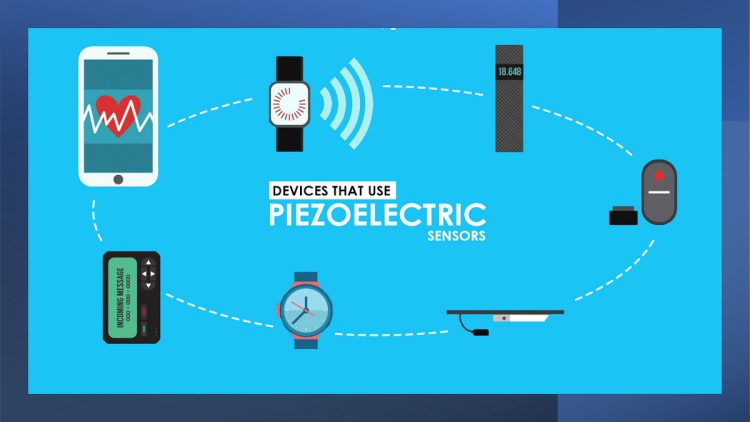

Dr. Mohsin Saleem from NUST School of Chemical and Materials Engineering along with his teammates have developed a way to produce the precursors for PZT by the use of natural mineral resources instead of importing them. The material extracted from the minerals can then be used to synthesize PZT powder of high quality which would later be utilized to produce application based piezoelectric devices such as biomedical, information technology/robotics, precision machines, ecological/energy harvesters, nondestructive testing transducers and measurement, piezoelectric sensors, acoustic devices and resonators, sonars, ultrasonic welding, ultrasonic cutting, gas ignition, and many other applications.

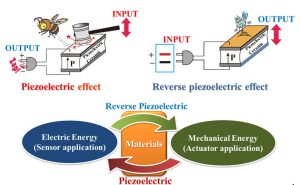

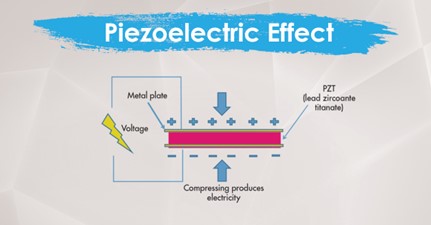

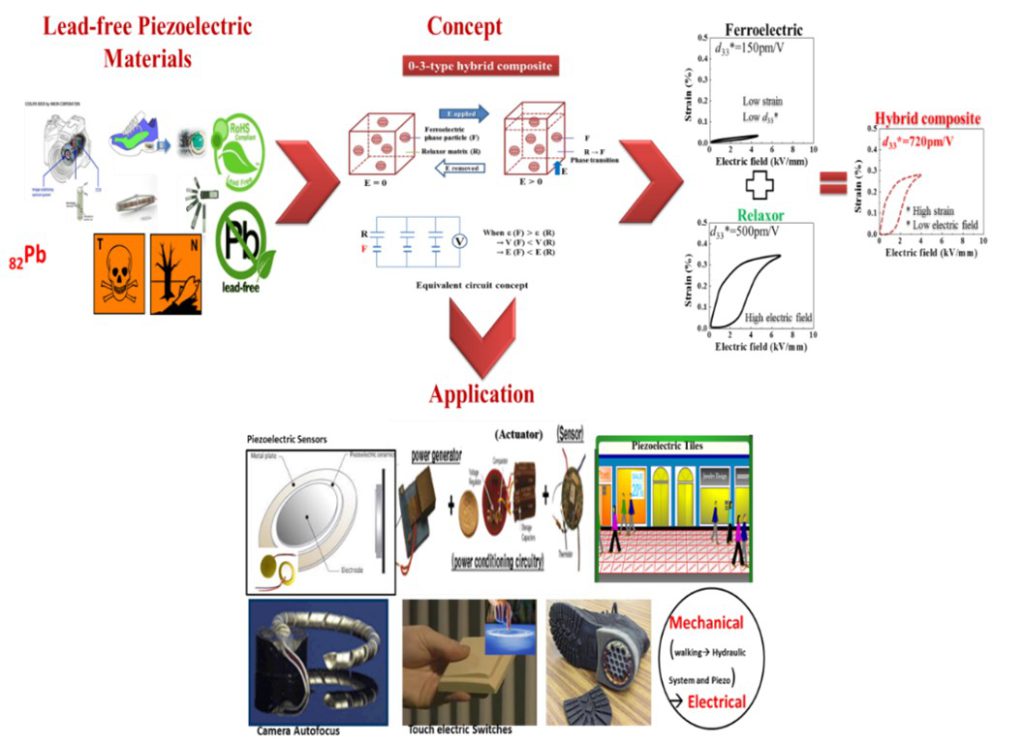

Piezoelectric Materials work on the phenomenon of piezoelectricity, which basically couples the mechanical and electrical responses of the materials. When a mechanical force is applied on a piezoelectric material, it produces electrical charge and on the other hand, the applied electric field generates mechanical deformation in them. Such astonishing properties of these materials make them a suitable candidate to be used in many applications such as energy storage, fluid control, optics, precision machining, accurate displacement, astronomy, and rapid response devices.

In electrical devices, piezoelectric actuators, car buzzers, and sensors have been made up from Pb-added piezoelectric materials (PZT), because of their exceptional electromechanical properties. Lead-based ceramics and their composites play an important role in piezoelectric applications. Our project will help to meet the requirements of affordable and clean energy by the use of Lead-based materials in sensors and actuators. It will also make sure access to affordable, reliable, sustainable, and modern energy for all. In this project, the main focus is to make a piezoelectric powder in lab/pilot-scale production and prototype at high quality and affordable price. All these piezoelectric devices are imported from abroad. Imports of the piezoelectric devices (multi-layered actuator, sensor, etc.) have burdened the national exchequer.

Numerous research efforts have been devoted to candidate lead-based and lead-free materials such as PZT, PMN-PNN-PZT, Bi0.5Na0.5TiO3 (BNT), Na0.5K0.5NbO3 (NKN), BaTiO3 (BT), and BiFeO3 (BF), because of their fascinating electromechanical properties.

The PZT-based ceramics are considered promising because of their high Curie temperatures (Tc ~ 825 oC) and a high theoretical spontaneous polarization (Pr ~100 μC/cm2). Moreover, this material (which has rhombohedral R3c structural symmetry) readily makes a solid solution with other perovskite materials that allow the formation of morphotropic phase boundary (MPB), at which the electromechanical performance is enhanced. This project will be focused on the synthesis and electromechanical characterization of the lead-free 1-xBiNaTiO3-xSrTiO3 (BNT-ST) bulk ceramics, and various compositional modification through site engineering with donor dopants. Based on phase transformation, these compositional designs and modifications in BNT-ST and BNT-ST-BNKT ceramics will enhance the electromechanical as well as the energy storage performance. Moreover, this project will allow us to develop basic infrastructure for the synthesis and characterization of piezoelectric & energy materials, train local graduates in this important field, and may find use in piezoelectric energy storage materials in the local industry, resulting in a reduction in import of these materials thereby and thus improve the country’s economy.

Since piezoelectric materials produce an electrical potential in response to an applied force or generate mechanical movement when subjected to an electric field such smart materials have become essential for modern society, especially in the fields of information storage, communications, industrial automation, medical diagnostics, etc. Due to their varied applications, piezoelectric materials have attracted long-lasting attention from both academic and industrial communities for several decades with many recent exciting findings.

References:

Shin, D. J., Lim, D. H., Saleem, M., & Jeong, S. J. (2021). Fabrication and stability of base metal electrode (Ni) on a perovskite oxide co-fired multilayer piezoelectric device. DOI: 10.1039/D1TC02658E.

The author is an Assistant Professor in the Department of Material Engineering at School of Chemical and Materials Engineering, National University of Sciences and Technology (NUST-SCME) and can be reached at mohsin.saleem@scme.nust.edu.pk.

Research Profile: https://bit.ly/3S3OYZE