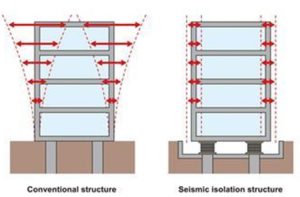

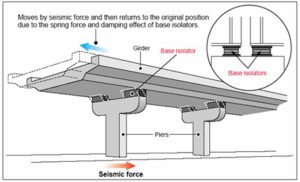

Earthquake is the shaking and vibration at the surface of the earth resulting from the underground movement along a fault plane or from volcanic activity. To negate the effect of these earthquakes, structures resistant to such shakings and vibrations should be built using several techniques. Many techniques have been in use. “Base isolation” is a technique that separates the structure and its components from the dangerous earthquake ground motions. Base isolation is achieved by mounting the superstructure on the system of supports made of Magnetorheological Elastomers (MRE) that are stiff and strong concerning vertical forces and show low stiffness in the horizontal direction. Particle size plays a vital role in the characterization of MRE.

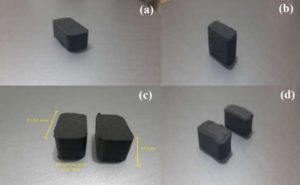

A better study is needed on the effect of using different particle size, specifically in range of nanoparticles obtained from the same source is required, as previous studies were mostly based on using fillers with particle size greater than or equals to 0.5 μm for MRE, very limited research has been done using nano-sized filler particles, for MRE based-base isolator. The new attribute of this study is to fabricate hybrid MRE, utilizing micro and nano-sized particles obtained from the same source. The purpose is to observe the effect of using different sizes of fillers in one composition, on the dynamic shear properties of MRE. Here silicon rubber as elastomeric matrix is considered with 10% silicon oil for soft MRE material. MR effect of MREs with different iron ratios including iron nanoparticles under shear loading is observed, also the effect of the hybrid nature of samples at large strain amplitudes is studied

The main aim of this research work is to determine the behaviour of MRE using Nickel and Cobalt and to compare the magnetorheological effect between them. Most of the research work has been done on MREs using carbonyl iron as filler material. The use of nickel and cobalt has been increasing in magnetic appliances in every field and their magnetic properties at the micro level are almost similar to carbonyl iron. So, CI was replaced with Ni and Co particles.

Methodology

- Characterization of metallic powders to determine size of particles and check for impurities.

- Casting of MRE samples.

- Micro-image analysis of casted MREs.

- Finally, the dynamic shear testing on the casted samples and the analysis of obtained results.

Results and Conclusion

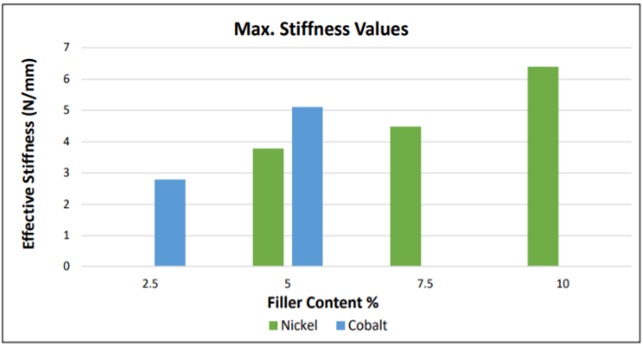

- For nickel and cobalt based MREs, change in effective stiffness with change in frequency is in line with the previous researches and less as compared to change in amplitude which shows amplitude dependent nature of MREs.

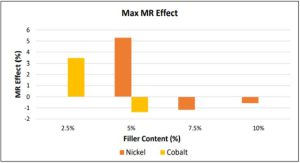

- For nickel and cobalt based MREs, MR effect increases with increase in frequency which is a new observation with microparticles and requires further research.

- For cobalt based MREs, MR effect with change in amplitude is in line with the literature. But for nickel based MREs, increase in MR effect is observed at 70% strain as compared to 50% strain which is a new observation and need more research.

References

- S.U.Khayam, M.Usman. Development and characterization of a novel hybrid magnetorheological elastomer incorporating micro and nano size iron fillers. Materials and Design, 2020.

DOI: https://doi.org/10.1016/j.matdes.2020.108748. - Anna Boczkowska; Stefan Awietjan. Microstructure and Properties of Magnetorheological Elastomer. Advanced Elastomers – Technology. 2012. DOI: http://dx.doi.org/10.5772/50430.

The author is Head of Structure Department, at School of Civil and Environmental Engineering (SCEE), National University of Sciences and Technology (NUST). He can be reached at m.usman@nice.nust.edu.pk.

Researcher’s Profile: https://scholar.google.com/citations?user=VmsfTWwAAAAJ&hl=en