The global construction industry is facing a huge upward challenge to keep up with the demands of rising population in the world. According to a study by ASCE in USA, which is one of the most progressive countries in the world, is facing a deficit of $3.6 trillion to construct new infrastructure and repair existing one. The number is only set to grow and estimated to achieve a deficit of $56 trillion dollars by 2050 if no innovation is brought into the construction industry. With the manufacturing industry continuously innovating new solutions to counter modern problems, the construction industry is decreasing in efficiency with the passage of time. Hence, we need to streamline our construction processes and adopt new construction technologies, such as Lean Construction, 3D printing, pre-fabricated construction, Modular homes and Automation in Construction.

The situation in Pakistan is even more dire, with an estimate of housing shortage over 10 million homes at the moment. The housing needs of Pakistan demands for rapid and economical residential and building construction to provide shelter for many. Conventional construction technologies and methods require extensive construction times, lack innovation, are resource heavy and contribute majorly to environmental degradation. Moreover, statistics states that China, India, Bangladesh and Pakistan are accountable for 90% of the world’s brick production, where brick is the culprit for 20% of the global black carbon emission; hence, Pakistan is one of the country’s most severely affected by global warming. To counter these problems, an innovative building system known as Light-Weight Insulated Concrete Panel, comprising of a wavy-shaped EPS insulation layer for thermal efficiency, is sandwiched between two innovative mortar layers, held together by system of shear connectors and wire-mesh reinforcement imbedded inside the mortar.

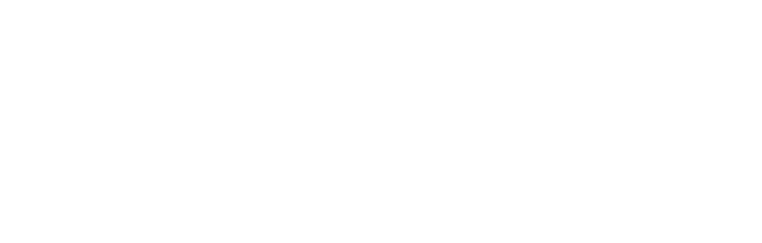

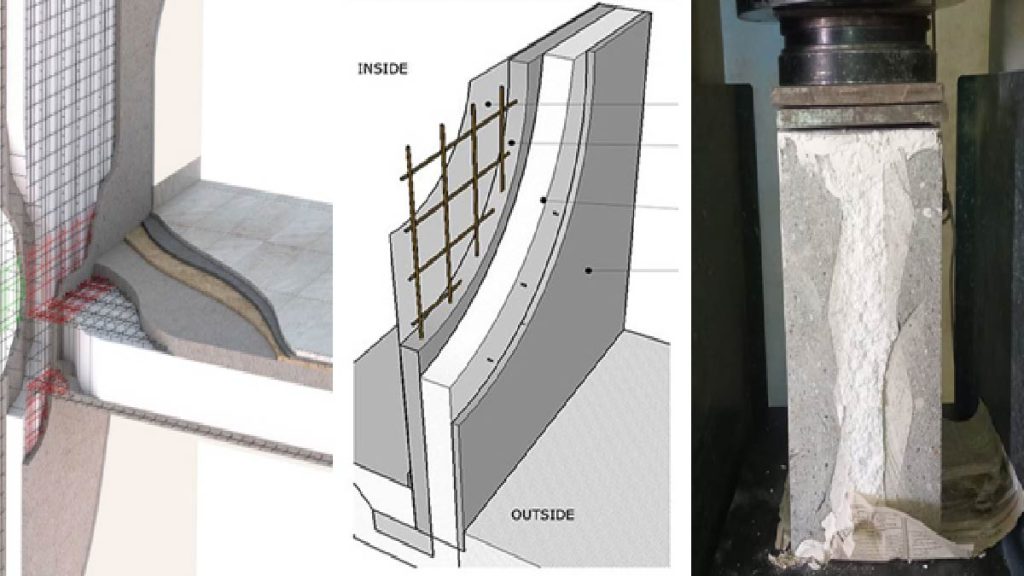

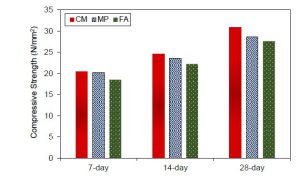

A research study was conducted by Dr. Rao Arsalan Khushnood and his team to develop “Light-Weight Insulated Concrete Panels for Residential Construction in Pakistan”.The present invention discloses the development and composition of light-weight insulated concrete panels which utilizes indigenous industrial waste materials; Waste Marble Powder (WMP) and Class C Fly Ash (FA), as partial cement replacement (15% by weight of cement), for its mortar layers in order to achieve better economy and sustainability and reduce harmful carbon emissions. While the mineral admixtures contribute little to mechanical strength of panels, they significantly reduce the tendency of mortar to shrink while bringing a positive change to the durability of the sample. The final panel geometry comprised of 50 mm mortar layers on either side of the insulation layer, an 80 mm thick insulation layer, a 65mm square reinforcing mesh composed of smooth galvanized steel bars of 3mm diameter for longitudinal strength and 2.5 mm diameter perpendicular steel shear connectors spaced at every 225 mm on the width of panels and 75 mm on the length of panels. The casted panels were scaled down to 1500 mm in height and 750 mm in length. The resulted panels were effectively three times lighter than concrete wall of similar dimensions, provided 46% better thermal insulation and over 50% reduction in carbon emissions when compared to conventional concrete and over 13 times fewer carbon emissions when compared to burnt brick. In addition, the uniaxial compression test revealed that a wall panel of 2.5’ x 1’ can bear up to 610 kN or 10 MPa of pressure, which is significantly higher than a brick wall, whereas the slab panel with can bear up to 35 kN, which comfortably fulfils the 27.9 kN design load criteria on a similarly dimension slab.

Concluding Remarks

Insulated Concrete Sandwich Panels, as a concept and technology, have been researched for a very long time now. Majority of the researches study the panels against lateral and wind loading, for the panels to be used for non-bearing purposes in high-rise buildings. The significance of this research is the focus on insulated concrete panels as construction elements for both load-bearing walls and slabs in Residential Construction specifically, with economy and sustainability as the main driving constraints. Economy and sustainability are achieved through the use of Industrial

The Construction Industry is stagnant in terms of innovation due to the marginal profits in comparison to the project costs. With the Building and Infrastructure Industry making up over 60% of the Construction Industry, innovation in Construction technologies and methodologies is essential. With the ability of panels to be manufactured inside a manufacturing plant and the potential for modular construction at site, it can bring down construction time and cost significantly, increase labour productivity, reduce usage of resources at site, streamline construction practices, reduce overall Construction and Demolition Pollution as they be assembled and dissembled at sight and overcome the hurdle of high transportation costs and collapse under seismic loading due to their lightweight nature.

The Insulated Concrete Panels (ICP) have the potential for overcoming the housing shortage of Pakistan due to their rapid construction potential and reduced construction costs. The ICP can become a vital contributor to the construction of homes under the Naya Pakistan Housing Scheme (NAPDHA) due to the repetitive nature of construction. In order to increase the integrity of the technology, a constructability review and a 1:1 scale model of house needs to constructed to evaluate the practical time, cost and ease of construction.

References

[1] Zafar, Muhammad & Javed, Usman & Khushnood, Rao & Nawaz, Adnan & Zafar, Tayyab. (2020). Sustainable incorporation of waste granite dust as partial replacement of sand in autoclave aerated concrete. Construction and Building Materials. 250. 118878. DOI: 10.1016/j.conbuildmat.2020.118878.

[2] Memon, Shazim & Javed, Usman & Khushnood, Rao & Kim, Jong. (2021). Incorporation of Wheat Straw Ash as Partial Sand Replacement for Production of Eco‐Friendly Concrete. Materials. 14. 2078. DOI: 10.3390/ma14082078.

[3] Memon, Shazim & Javed, Usman & Khushnood, Rao. (2018). Eco-friendly utilization of corncob ash as partial replacement of sand in concrete. Construction and Building Materials. 195. 165-177. DOI: 10.1016/j.conbuildmat.2018.11.063.

The author is HoD Research at Structures Department, School of Civil and Environmental Engineering, National University of Sciences & Technology (NUST). He can be reached at [email protected].

Author’s Research Profile: https://scholar.google.com.pk/citations?user=amqbrlIAAAAJ&hl=en.