Agricultural production has grown significantly over the last few decades to meet the demands of the augmented population worldwide. Although agricultural growth is important from the food security and economic point of view, this has exacerbated the waste management issue demanding sustainable solutions. Among all the agricultural wastes, crop straw shares a major chunk; for instance, according to research, in China alone, out of 1.75 × 109 tons of agricultural waste annually, approximately 9.93 × 108 tons are of crop straw. Meanwhile, wheat is one of the major crops which yield an annual straw of 8.0 × 107 tons in China, 1.44 × 108 tons in Europe, and 5.29 × 108 tons worldwide demanding serious waste management efforts. Furthermore, wheat straw (WS) contains cellulose, which persists in the environment and continues to be a pollutant. With the exception of some amount of WS that is used to make paper or livestock feed, the vast amount of WS is burned or dumped as an environmental hazard. In addition, WS has a low resource utilization rate (less than 40%), which signifies that most of the WS act as a pollution source or waste management burden. Thus, more innovative resource utilization ideas of WS should be proposed and assessed for real-scale implementations. The construction sector is a potential resource utilization avenue for various waste byproducts, as there are several environmental and human health benefits of using locally sourced, natural, and renewable waste materials, such as agricultural waste, as construction materials. Therefore, it is envisaged that the solutions promoting the utilization of WS with minimal screening can present a win-win situation for waste management, environmental protection, and the construction sector.

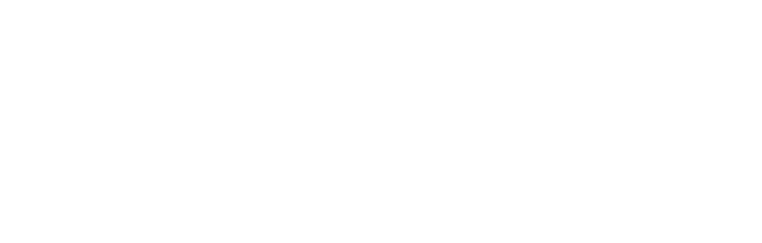

On the other hand, silica fume (SF) is a byproduct of the ferrosilicon or silicon alloy manufacturing industry, and it is a kind of industrial waste generated in a large quantity during the production process. The annual generation of SF is 1.0 × 106 tons worldwide. Hence, the safe disposal of SF is a severe problem in itself because open environment disposal can cause severe health issues. Consequently, the utilization of SF in several civil engineering applications offers a significant advantage in an environmentally sustainable way. The governing oxide in SF is silicon dioxide (SiO2) which makes SF a pozzolanic additive, and it has a large surface area of 1590 m2/kg. Overall, performance of SF as a soil stabilizer with or without other additives, is very beneficial considering geotechnical characteristics. So, it is a good option to integrate the SF with the WS because the key chemical component in the SF is SiO2 which reacts with CaO available in the soil-stabilizer mixture and generates cementitious gel. Figure 1 depicts the flowchart of the use of WS and SF (agri-industrial wastes) in the construction sector as postulated by the current study.

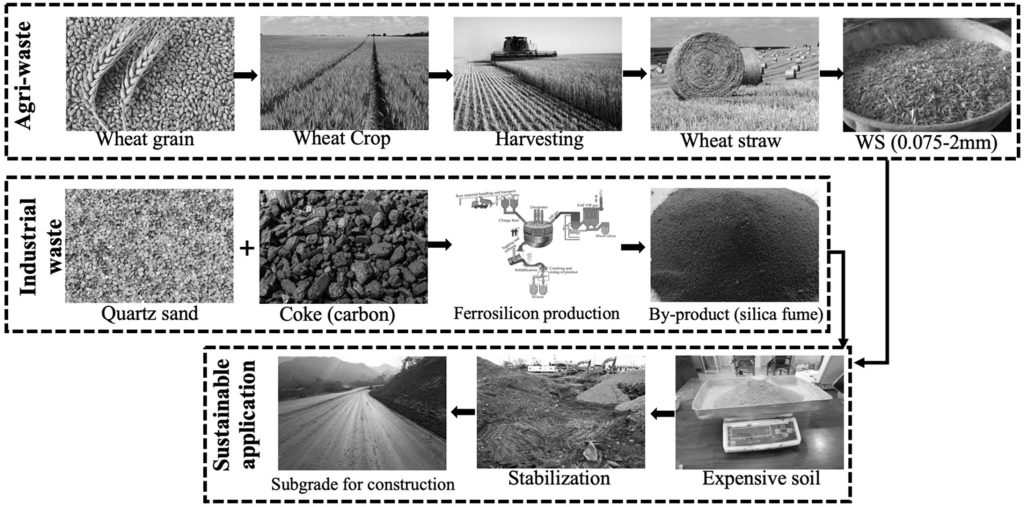

Considering aforementioned discussion, resource utilization of agricultural and industrial wastes with minimal screening is highly desirable in the context of sustainable development and environmental protection. In this regard, the current study proposes a novel solution of integrating milled WS with minimal screening and SF in the form of composite binary admixture (CBA) for the stabilization of highly expansive soils. The optimum amount of WS and SF to produce CBA was determined based on a series of Atterberg’s limit tests. The mechanical performance of CBA-treated soil was assessed based on the unconfined compression, direct shear, and flexural tests which showed that unconfined compressive strength (qu), cohesion (c), and flexural strength (f) were increased by 94.3%, 65.7%, and 90.7%, respectively, with an addition of 16% of CBA and 28 days of curing. Furthermore, the CBA-treated soil underwent only a 26% reduction in deformability index (ID) with an addition of 24% CBA. The impact of CBA on f, qu, and ID is illustrated in Figure 2 in detail.

Furthermore, volumetric change response was assessed based on ID consolidation and swelling tests which showed that compression index (Cc), recompression index (Cr), swell potential, free swell index (FSI), and swell pressure were reduced by 72.5%, 47.7%, 59%, 35.8%, and 65%, respectively, with an addition of 16% CBA in the soil and 28 days of curing. In addition, wetting-drying (W-D) cycle tests demonstrated that CBA-treated soil was less vulnerable to W-D seasons as compared to untreated soil. Mineralogical and microstructural tests revealed that the balanced Ca:Si and Ca:Al environment created by CBA within the soil matrix produces cementing compounds, i.e., CSH and CAH, imparts strong bonds, and causes aggregation improving the mechanical response of expansive soil.

Reference:

Khalid U, Rehman Z, Ijaz N, Khan I, Junaid MF, (May, 2023). Integrating wheat straw and silica fume as a balanced mechanical ameliorator for expansive soil: a novel agri‑industrial waste solution. Environmental Science and Pollution Research 30, 73570–73589.

The author is Assistant Professor and Director Local Quality Enhancement Cell at National Institute of Transportation, Risalpur, National University of Sciences and Technology (NUST). He can be reached at [email protected].

Research Profile: https://shorturl.at/gmS08

![]()