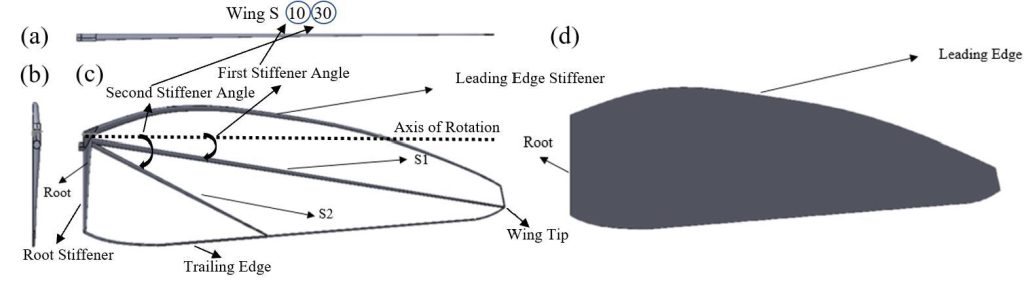

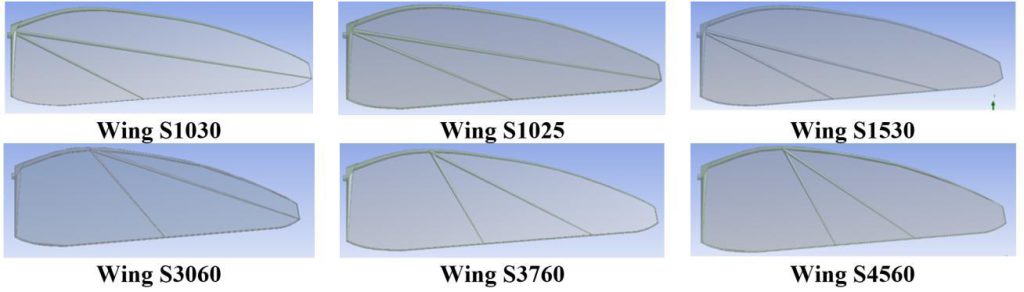

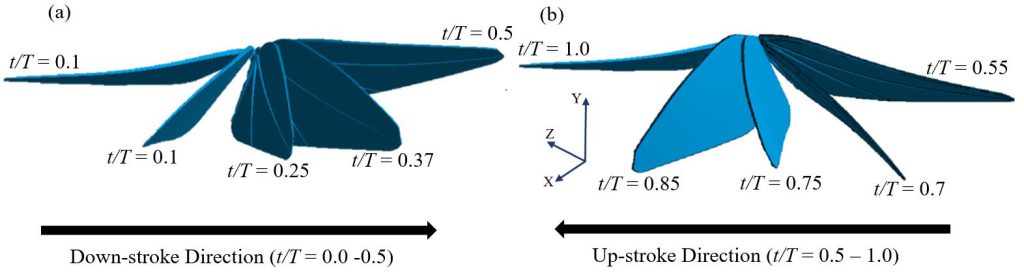

Flapping wing micro aerial vehicles are studied as the substitute for fixed and rotary wing micro aerial vehicles because of the advantages such as agility, maneuverability, and employability in confined environments. Hummingbird’s sustainable hovering capability inspires many researchers to develop micro aerial vehicles with similar dynamics. In this research, a wing of a ruby-throated hummingbird is modelled as an insect wing using membrane and stiffeners. The effect of flexibility on the aerodynamic performance of a wing in hovering flight has been studied numerically by using a Fluid-Structure Interaction scheme at a Reynolds Number of 3000. Different wings have been developed by using different positions and thicknesses of the stiffeners. The chord wise and span wise flexural stiffness’s of all the wings modelled in this work are comparable to insects of similar span and chord length. When the position of the stiffener is varied, the best-performing wing has an average lift coefficient of 0.51. Subsequently, the average lift coefficient is increased to 0.56 when the appropriate thickness of the stiffeners is chosen. The best flexible wing outperforms its rigid counterpart and produces lift and power economy comparable to a real hummingbird’s wing. That is, the average lift coefficient and power economy of 0.56 and 0.88 for the best flexible wing as compared to 0.61 and 1.07 for the hummingbird’s wing. It can be concluded that a simple manufactural flexible wing design based on appropriate positioning and thickness of stiffeners can serve as a potential candidate for bio-inspired flapping-wing Micro Aerial Vehicles.

Flapping wing micro aerial vehicles are studied as the substitute for fixed and rotary wing micro aerial vehicles because of the advantages such as agility, maneuverability, and employability in confined environments. Hummingbird’s sustainable hovering capability inspires many researchers to develop micro aerial vehicles with similar dynamics. In this research, a wing of a ruby-throated hummingbird is modelled as an insect wing using membrane and stiffeners. The effect of flexibility on the aerodynamic performance of a wing in hovering flight has been studied numerically by using a Fluid-Structure Interaction scheme at a Reynolds Number of 3000. Different wings have been developed by using different positions and thicknesses of the stiffeners. The chord wise and span wise flexural stiffness’s of all the wings modelled in this work are comparable to insects of similar span and chord length. When the position of the stiffener is varied, the best-performing wing has an average lift coefficient of 0.51. Subsequently, the average lift coefficient is increased to 0.56 when the appropriate thickness of the stiffeners is chosen. The best flexible wing outperforms its rigid counterpart and produces lift and power economy comparable to a real hummingbird’s wing. That is, the average lift coefficient and power economy of 0.56 and 0.88 for the best flexible wing as compared to 0.61 and 1.07 for the hummingbird’s wing. It can be concluded that a simple manufactural flexible wing design based on appropriate positioning and thickness of stiffeners can serve as a potential candidate for bio-inspired flapping-wing Micro Aerial Vehicles.

![Figure 1: Kinematics of the ruby-throated hummingbird; (a) definition of stroke angle (φ), pitch angle (α), and deviation angle (θ) for this study, (b) time history of kinematics angles in hovering motion, and (c and d) the definition of the mid-span pitch angle of rigid and flexible wings in which the filled circle represents the leading edge [1]](https://researchblog.nust.edu.pk/wp-content/uploads/2021/11/Figure-1-A1-300x208.jpg)

(b) wing position for Wing S3S4 for the upstroke

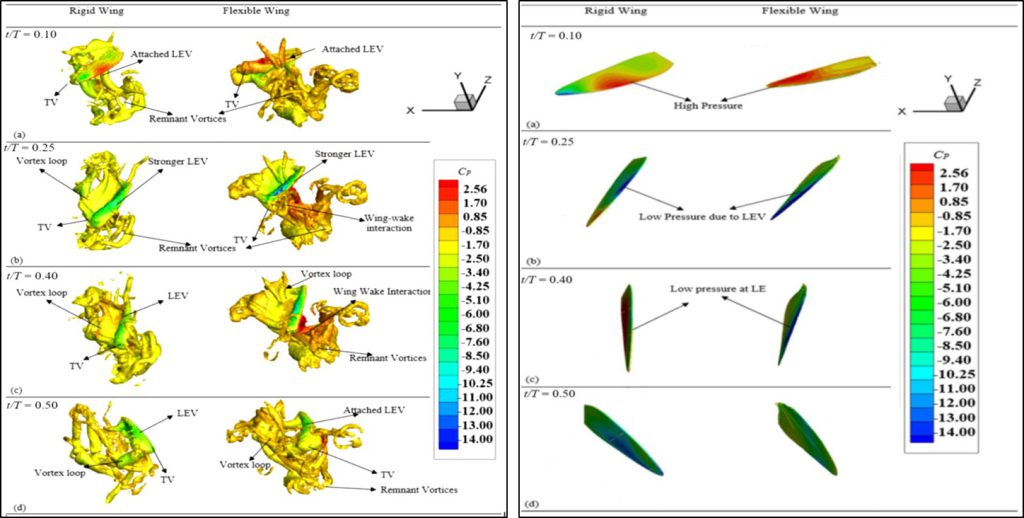

In this research, the effect of wing flexibility on aerodynamic performance has been numerically investigated. The Fluid-Structure Interaction analysis is performed by coupling the 3D, viscous, incompressible Naiver–Stokes equations with structure solver for the ruby-throated hummingbird hovering motion at Reynold number of 3000. Results have shown that the lift coefficient of the flexible wing increases till the optimum value of the flexibility. Parametric studies show that the position of the stiffener affects the flexibility of the wing. The wing in which the surface stiffener covers the surface uniformly yields the maximum lift coefficient. If either stiffener is missing some surface like wingtip in wing S1530 (leads to more flexibility at wingtip) or the wing with high stiffness like wing S3060 will yield less lift output. Similarly, a parametric study for the thickness of the wing stiffeners has shown that the wing with optimized flexibility yield higher lift output. The wing with more stiffness like wing S7S8 than wing S3S4 or wing with less stiffness like wing S5S6 yields lower lift output. The best wing S3S4 among all the cases is compared with the rigid wing. A flexible wing produces more lift than a rigid wing. The average lift coefficient of the flexible wing is 0.56 as compared to 0.48 for the rigid wing.

Flow field analysis showed that unsteady features like LEVs, TEVs, TVs, and wing wake interaction have a major effect on aerodynamics performance. The higher vortex intensity of the LEV for the flexible wing was one of the main reasons for the higher lift coefficient. Attached LEV and vortex loop formation were observed during the down stroke. Due to the LEV, TEV, and TV, stronger lower pressure regions were created. Which were the main reason for the higher lift coefficient. Wing wake interaction was observed during the upstroke. Comparative analysis of the designed flexible wing with the ruby-throated hummingbird wing was carried out. The average lift coefficient for the flexible wing was 0.56 whereas for the ruby-throated wing was 0.61. The flexible wing with 𝐶𝐿of 0.56 can support the weight (3.4 grams) of the ruby-throated hummingbird. The wing of a real hummingbird has a complex structure based on muscles and feathers which is not easy to replicate for manufacturing. Hence, for MAVs application, it is desirable to use a simple manufactural flexible wing based on stiffeners and membrane as it can produce lift and power economy comparable to a real hummingbird’s wing.

References:

- Song J, Luo H, Hedrick TL. Three-dimensional flow and lift characteristics of a hovering ruby-throated hummingbird. Journal of The Royal Society Interface. 2014 Sep 6;11(98):20140541.

- Keennon, Matthew, Karl Klingebiel, and Henry Won. “Development of the nano hummingbird: A tailless flapping wing micro air vehicle.” In 50th AIAA aerospace sciences meeting including the new horizons forum and aerospace exposition, p. 588. 2012.

- Shyy, Wei, Chang-kwon Kang, Pakpong Chirarattananon, Sridhar Ravi, and Hao Liu. “Aerodynamics, sensing and control of insect-scale flapping-wing flight.” Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 472, no. 2186 (2016): 20150712.

- Zhang C, Rossi C. A review of compliant transmission mechanisms for bio-inspired flapping-wing micro air vehicles. Bioinspiration & biomimetics. 2017 Feb 15;12(2):025005

- Estrada MA, Mintchev S, Christensen DL, Cutkosky MR, Floreano D. Forceful manipulation with micro air vehicles. Science Robotics. 2018 Oct 24;3(23).

- Woods, M. I., J. F. Henderson, and G. D. Lock. “Energy requirements for the flight of micro air vehicles.” The Aeronautical Journal 105, no. 1045 (2001): 135-149.

The author is an Assistant Professor at Department of Aerospace Engineering, College of Aeronautical Engineering, National University of Sciences and Technology (NUST) and can be reached at [email protected].