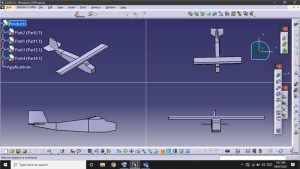

NED University of Engineering and Technology, PropellAir’21 was hosted by IMechE NEDUET Student Chapter. In the event, the participants had to design, fabricate and ultimately fly an unmanned aircraft. The event comprised of workshops, oral exam and e-test of participants, and actual flight demonstrations of handmade aircraft. The final contest was held on Saturday, July 10, 2021, at the football ground of the University of Karachi. Out of the thirteen participating teams, the winner of PropellAir’21 was Team Falcon from the College of Aeronautical Engineering, CAE, NUST, Risalpur. The design and fabrication task was carried out the Aerospace Vehicle Design Lab, College of Aeronautical Engineering, Risalpur. The fabrication was done using the different other labs (such as the Industrial Engineering Lab) within the premises of CAE. Apart from all the weight considerations and efforts to reduce the weight, no compromise was made upon the structural integrity of the UAV, causing it to be a little tail heavy.

NED University of Engineering and Technology, PropellAir’21 was hosted by IMechE NEDUET Student Chapter. In the event, the participants had to design, fabricate and ultimately fly an unmanned aircraft. The event comprised of workshops, oral exam and e-test of participants, and actual flight demonstrations of handmade aircraft. The final contest was held on Saturday, July 10, 2021, at the football ground of the University of Karachi. Out of the thirteen participating teams, the winner of PropellAir’21 was Team Falcon from the College of Aeronautical Engineering, CAE, NUST, Risalpur. The design and fabrication task was carried out the Aerospace Vehicle Design Lab, College of Aeronautical Engineering, Risalpur. The fabrication was done using the different other labs (such as the Industrial Engineering Lab) within the premises of CAE. Apart from all the weight considerations and efforts to reduce the weight, no compromise was made upon the structural integrity of the UAV, causing it to be a little tail heavy.

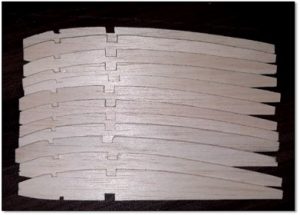

UAV Structure Fabrication

Making a balsa and plywood fuselage was easiest but the weight control over epoxy was difficult but still it provided far better strength than foam. So traditional balsa and plywood fuselage used in RC models was considered. First of all, the construction of all fuselage parts started. All the pieces were first, according to respective dimensions were marked and cut. To reduce the weight holes were cut, where possible in the fuselage walls. Required slots and cut outs were made for the wing and horizontal and vertical stabilizers. The part was landing gear and firewall were to be mounted were reinforced with extra layers of plywood. All the main parts of fuselage were put together to form its basic shape. Balsa was doubled near the wing, landing gear and firewall area for adequate strength. Then the firewall was made out of 2mm balsa and plywood glued together so that it should have the required strength for the motor. Battery bay was made according to the size of the battery with doubled balsa sheet. It was made so as to restrict the battery in its specific place, not allowing it to move here and there. Of course, it was subjected to change according to CG. Servo plate made of ply and good enough to accommodate two servos for rudder and elevator was install inside the fuselage beneath the wing mount. Canopy of the fuselage which was also made of balsa and covered in monocot sheet was fixed in its respective place. Finally, the holes for the dowels, which were to hold the rubber bands for wing were made and the dowels were installed. The fuselage was finished by installing the access panel for the battery.

Epler 193 was selected for wing. 14 Eppler 193 airfoils were made from balsa wood. These air foils were then arranged to form wing with a 2 degrees’ dihedral angle. Front surface was laminated with minimum thickness balsa to provide strength. Ailerons were then installed at the locations as specified in the design. Complete wing was then laminated using monocot sheet of red and white color. Some extra weight saving effort was required in the case of tails as they are located at a considerable moment arm so any weight penalty can cause C.G balance problems. Balsa cut outs were made of the required length, both of the horizontal and vertical stabilizers. The elevator and rudder both were also of balsa. Stabilizers were laminated with monocot sheet. The same was done with both rudder and elevator. The payload mechanism was installed on the lower surface of the aircraft near the centre of gravity of the aircraft so that the stability of the aircraft is not affected much. A servo was installed which was connected to the radio transmitter switch used to drop the payload in the desired area.

Ground and Flight Testing of UAV

(a) Ground Testing

(i) Wing strength test. Point loads of up to 3 kg were applied to test the structural integrity of the wing. The wing was structurally rigid enough to bear the aerodynamic loads and the weight of the aircraft.

(ii) Drop test. The aircraft was dropped from a height of 1.5 ft. and it was an impact test for the landing gears. The UAV passed the test successfully.

(b) Flight Test

First flight test was carried out at Polo Field PAF Academy, Risalpur. It was a successful test with the aircraft performing all the basic maneuvers as per the competition RFPs. The circuits were successful. and the vertical loops were also successful.

The design and development of FALCON UAV was a very unique experience for the students where lot was learned. The future of Aerospace Industry does not belong to manned aircraft but flying robots of all sizes and ranges to fulfil the entire range of future missions. Propellair is a very positive initiative to encourage young students to focus on the design and development of UAVs. The way the UAVs are progressing, it is not far off that designers will be producing UAV not only to suffice their defense industry needs, but to meet all the requirements of Private Sector Organizations. These UAVs have the advantage of penetrating into dirty, dull and dangerous environments. Practical experiences learnt during the development of FALCON will be very useful for all such future endeavours.

References:

(i) The Design and Construction of Flying Model Aircraft by D. A. Russell

(ii) R. Nelson, Flight Stability and Automatic Control.

(iii) Yechout, R. Thomas, Introduction to Flight Mechanics, (AIAA)

(iv) Nicolai, Leland M., Fundamentals of Aircraft and Airship Design (AIAA)

(v) Sadraey, Mohammad H., Aircraft Design A Systems Engineering Approach (Wiley)

The author is Lecturer at Department of Aerospace Engineering, College of Aeronautical Engineering, National University of Sciences and Technology (NUST) and can be reached at [email protected].