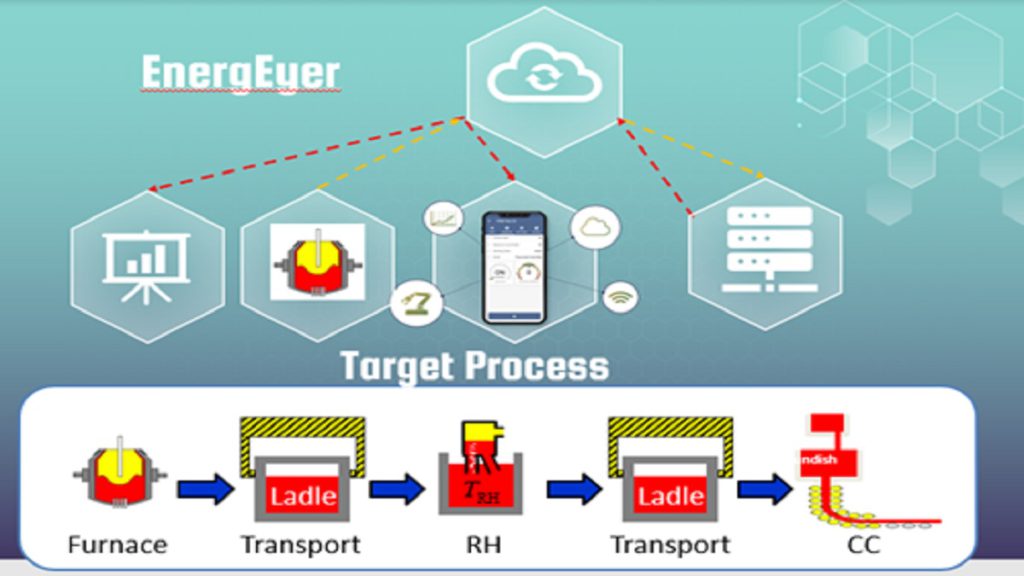

Energy conservation opportunities in Pakistan are estimated to be 5 billion USD a year with a substantial share of 25% for industry. One of the several ways of energy saving in the industrial sector is implementation of an integrated Energy Management System (EMS). However, like other developing countries, EMS in process industries of Pakistan involves manual calculations and is not fully robust and integrated. Hence, a substantial amount of energy is lost which causes damage to the national economy, wastage of national resources, and adversely affects the environment. A research team from the National University of Sciences and Technology (NUST) developed a prototype of an Intelligent Energy Monitoring and Management System namely EnergEyer for process industries by incorporating the concepts of artificial intelligence, wireless communication, and cloud computing in the conventional EMS. The EnergEyer was successfully implemented in the MAT CAST Plant of Fazal Steel Limited (FSL). The project was financed by the FSL with active technical support from the United Nations Industrial Development Organization (UNIDO), Pakistan.

Energy conservation opportunities in Pakistan are estimated to be 5 billion USD a year with a substantial share of 25% for industry. One of the several ways of energy saving in the industrial sector is implementation of an integrated Energy Management System (EMS). However, like other developing countries, EMS in process industries of Pakistan involves manual calculations and is not fully robust and integrated. Hence, a substantial amount of energy is lost which causes damage to the national economy, wastage of national resources, and adversely affects the environment. A research team from the National University of Sciences and Technology (NUST) developed a prototype of an Intelligent Energy Monitoring and Management System namely EnergEyer for process industries by incorporating the concepts of artificial intelligence, wireless communication, and cloud computing in the conventional EMS. The EnergEyer was successfully implemented in the MAT CAST Plant of Fazal Steel Limited (FSL). The project was financed by the FSL with active technical support from the United Nations Industrial Development Organization (UNIDO), Pakistan.

The project’s Principal Investigator was Dr. Iftikhar from the School of Chemical and Materials Engineering (SCME) NUST accompanied by Dr. Mian Ilyas Ahmad as a Co-Principal Investigator from Research Centre for Modeling and Simulation (RCMS) NUST. Engr. Jihad Sallah Khan and Engr. Mohsin Mehmood were coordinators for the project from NUST and FSL, respectively. Mr. Masroor Ahmed Khan, the Country Project Manager on Energy Efficiency at UNIDO, was involved in the supervision of the project. International collaborators included Professor Dr. Patrik Thollander from Linköping University Sweden, and Professor Manabu Kano from Kyoto University Japan.

Implementation of EnergEyer makes FSL the pioneer from steel sector in joining the developed world in the industry 4.0 revolution. PC as well as mobile dashboards of EnergEyer make industry management and technical staff able to perform remote/wireless monitoring of the plant. EnergEyer is first of its kind in the local market and provides an easy and cheap solution to the local industries. The project is supportive of national sustainability goals and will help the local manufacturing sector in getting more recognition in the market and increase in profitability. The NUST team launched a Startup named Entriangle Inc. for commercialization of the EnergEyer in Iron and Steel sector as well as other process industries in Pakistan.

The inaugural ceremony for the commissioning of the EnergEyer was held at MATCAST plant of FSL. The chief guest Dr. Rizwan Riaz, NUST Pro-Rector Research, Innovation & Commercialization, unveiled the plaque at the ceremony attended by representatives of NUST, UNIDO, and the Fazal Group of Companies. Expressing his views, the chief guest thanked FSL Group of Companies for investing in and facilitating the project that would help bring the advanced technology to the fore. He also appreciated UNIDO and Fazal Steel for joining hands with NUST to successfully undertake this initiative of paramount significance. He also looked forward to forging meaningful partnerships with FSL in the future.

Mr. Masroor Ahmed Khan, National Project Manager Sustainable Energy REEE UNIDO, speaking on behalf of Ms. Nadia Aftab, UNIDO Country Representative said, “UNIDO in Pakistan has an extensive and successful portfolio in industrial development cooperation. While UNIDO is providing technical support to Fazal Steel in its goal to achieve Energy Management System Certification ISO 50001, under one of its flagship projects on Energy Efficiency, it is heartening to see growing and effective collaboration between academia and the industry.”

Earlier, Mr. Saad Aziz Malik of Fazal Steel welcomed all participants and thanked NUST and UNIDO for their invaluable contributions to the project. He said that it is a huge step towards encouraging the industry-academia relationship that would help us become a self-reliant nation.

The author is an Associate Professor at School of Chemical and Materials Engineering (SCME), Department of Chemical Engineering, National University of Sciences and Technology (NUST). He can be reached at [email protected].